DTF Transfers, or Direct-to-Film Transfers, have emerged as a revolutionary printing technology that stands in contrast to traditional printing methods. In the dynamic landscape of the printing industry, businesses and artists face the challenge of selecting the ideal technique, often debating DTF compared to more established practices. This article will dive into the benefits of DTF printing, from its cost-effectiveness for shorter runs to its impressive quality and detail that outshines other techniques, such as screen printing. Additionally, we will explore the pros and cons of DTF, ensuring a comprehensive understanding of where it stands in relation to traditional methods. Join us as we uncover the nuances of DTF transfer techniques, empowering you to make informed decisions on your printing endeavors.

When discussing the different methodologies in the printing sector, the distinction between Direct-to-Film (DTF) Transfers and conventional printing tactics often arises. This topic is not just relevant for businesses, but also for artists and fashion designers who constantly seek the most effective printing solutions. By examining the merits and limitations of DTF alongside traditional techniques, one can appreciate their unique applications and impacts. Alternative methods like screen printing and Direct-to-Garment printing have also shaped the landscape, providing diverse options for various needs. Understanding these different printing processes through the lens of efficiency, quality, and adaptability will be pivotal for anyone aiming to delve into the world of textile printing.

Understanding DTF Transfers: A Game-Changer in Printing

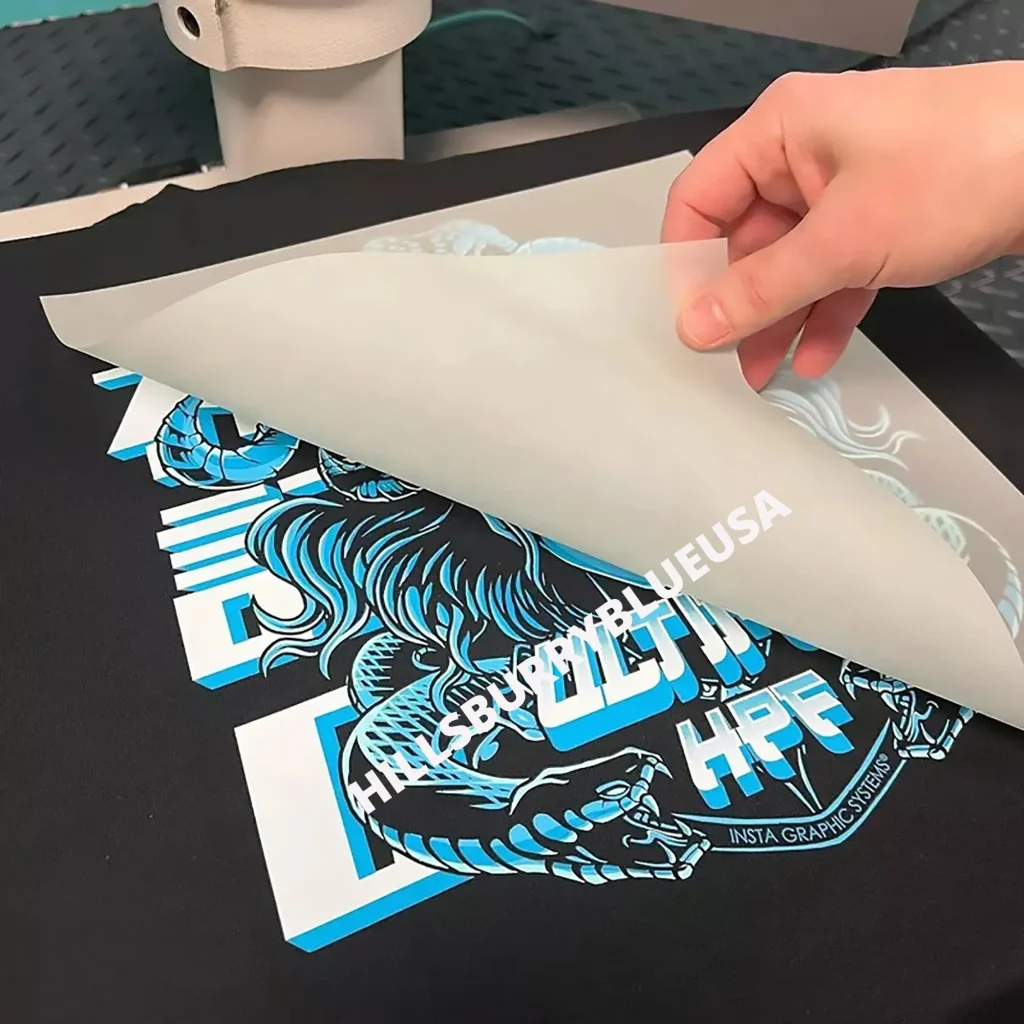

**Direct-to-Film (DTF) Transfers** have revolutionized the printing landscape, offering a fresh alternative to traditional techniques. Unlike standard methods, DTF involves printing designs onto a film, which is then transferred to the textile using heat. This innovative process allows for a vibrant palette of colors and intricate designs, catering to artists and businesses seeking creative expression. The DTF transfer technique is becoming increasingly popular due to its versatility, enabling prints on a variety of fabric types, including cotton, polyester, and blends.

Moreover, the **Benefits of DTF printing** extend beyond mere aesthetic appeal. DTF printing allows for full-color designs to be produced quickly and efficiently, making it especially appealing for businesses focusing on short runs or custom orders. This technology reduces waste since errors in design can be minimized through the use of films that can be easily altered without requiring extensive setup costs tied to traditional printing techniques.

Pros and Cons of DTF Transfers

The **Pros and Cons of DTF** are vital when choosing a printing method. Among the advantages, the ability to produce high-quality prints on various materials stands out. DTF transfers deliver exceptional detail and color vibrancy that can often surpass that of traditional methods. This makes them ideal for applications such as fashion design and promotional products. Additionally, the setup process for DTF printing is relatively straightforward, reducing the time needed to start production, particularly for custom orders.

However, the technique does come with some drawbacks. Reports indicate that prints created through DTF may not be as durable as those made by traditional methods, such as screen printing, especially after multiple washes. Furthermore, initial equipment costs for starting a DTF printing operation can be a hurdle for small business owners, who may also worry about the environmental impact associated with inks and materials used in this process.

Traditional Printing Techniques: An Overview

When considering **Traditional Printing**, methods like screen printing and Direct-to-Garment (DTG) come into play. These techniques have stood the test of time, boasting extensive refinements and established workflows that many businesses trust. A primary advantage is the durability of the prints, which often retain their vibrancy even after numerous washes. This reliability makes traditional printing the go-to method for items that need to withstand regular use, such as uniforms and promotional apparel.

However, traditional printing is not without its challenges. The **setup time and costs** are generally higher, especially when multi-color designs are involved. Moreover, screen printing and other traditional methods may lack the design flexibility that DTF printing provides. Complex images can be problematic, as these methods often struggle to replicate intricate details effectively, which can limit creative possibilities.

DTF Transfers vs. Screen Printing: A Direct Comparison

The debate between **DTF Transfers vs. Screen Printing** is particularly relevant for those in fashion and merchandise design. While both methods have their merits, they serve different needs within the industry. DTF printing excels in versatility, allowing for high-resolution designs on a variety of fabrics. Additionally, it is more economically feasible for small orders, giving artists and small businesses a viable option for their custom printing needs.

On the other hand, screen printing remains a powerhouse for bulk orders, particularly when simplicity in design is key. It tends to be more cost-effective for large runs, but the initial setup time can deter those seeking quick, small-scale production. Thus, businesses must assess their project requirements carefully, weighing the benefits of **DTF transfer techniques** against the reliability of traditional screen printing methods.

The Environmental Impact of DTF and Traditional Methods

Both DTF and traditional printing methods can have significant **environmental impacts**, which is a crucial consideration as businesses become more sustainability-conscious. DTF printing utilizes specific inks and materials that, while innovative, may not always be eco-friendly. The production of films and the finite resources involved in the process can contribute to a larger carbon footprint.

Conversely, traditional methods, particularly screen printing, have been optimizing resource use over the years but still face criticism regarding waste generation. Eco-friendly practices are becoming increasingly vital; businesses must choose their printing method wisely, keeping in mind not just the immediate costs and benefits but also the long-term implications for the environment.

Cost-Effectiveness in DTF vs. Traditional Printing

When it comes to **cost-effectiveness**, understanding the financial implications of DTF transfers compared to traditional printing techniques is crucial for businesses. DTF printing presents a favorable option for short runs due to its lower setup costs and reduced material waste. This makes it an appealing choice for designers and entrepreneurs looking for flexibility without investing heavily in preliminary costs.

In contrast, traditional printing methods, especially screen printing, might provide better cost efficiency for larger production runs. This method allows for economies of scale, significantly lowering the cost per unit as the quantity increases. However, the initial investment related to screen setup can be steep, making DTF a smarter choice for small-batch production where reducing overhead is critical.

Frequently Asked Questions

What are the main benefits of DTF Transfers compared to traditional printing?

DTF Transfers offer several advantages over traditional printing methods, such as versatility across various fabric types, vibrant colors, and intricate designs. They are particularly cost-effective for short production runs, minimizing setup costs and material waste.

How do DTF Transfers compare with screen printing in terms of quality?

When comparing DTF Transfers to screen printing, DTF tends to excel in producing detailed and colorful designs due to its advanced ink application on film, which can capture intricate details better than traditional screen printing.

What are the potential durability issues with DTF Transfers?

Although DTF Transfers provide high-quality prints, there are concerns about their durability; some users report that DTF prints may not withstand multiple washes as effectively as some traditional printing methods like screen printing.

Is DTF printing more cost-effective than traditional printing techniques?

Yes, DTF printing can be more cost-effective for smaller runs because it has lower setup costs compared to traditional methods, especially screen printing, which requires significant upfront investment for color separation.

What factors should be considered when choosing between DTF Transfers and traditional printing?

When choosing between DTF Transfers and traditional printing, consider factors such as the type of fabric, desired print quality, project scale, and specific design complexity, as DTF offers versatility, while traditional methods provide durability.

What are the environmental impacts of DTF Transfers versus traditional printing methods?

Both DTF Transfers and traditional printing methods can have environmental impacts, particularly concerning the materials used in inks and processes. However, DTF may generate less waste with shorter runs, while traditional methods might require more resources for setup.

| Key Points | DTF Transfers | Traditional Printing |

|---|---|---|

| Versatility | Compatible with various fabrics: cotton, polyester, blends. | Limited by materials; may not work well with all types of fabrics. |

| Quality and Detail | High-quality images with vibrant colors and intricate designs. | Can struggle with fine details and complex designs compared to DTF. |

| Cost-Effectiveness for Short Runs | Lower setup costs for small production runs; financially savvy. | Higher upfront costs and setup time needed for multi-color designs. |

| Reduced Material Waste | Minimizes waste compared to traditional methods. | Higher ink and material use, especially in multi-color prints. |

| Durability Concerns | Prints may not withstand frequent washing as well as traditional prints. | Highly durable, retains color and withstands multiple washes. |

| Equipment Expenses | Requires investment in specific equipment like heat presses. | More established equipment widely available, typically less initial investment. |

| Environmental Impact | Can have a notable environmental footprint based on materials used. | Environmental concerns based on ink and resource use. |

Summary

DTF Transfers represent a modern approach to printing, offering extensive benefits that cater to diverse fabric types and design complexities. Unlike traditional printing, which excels in durability and cost-effectiveness for larger runs, DTF Transfers shine in versatility and detail for smaller production needs. The choice between DTF Transfers and traditional printing ultimately hinges on factors like project scale and material compatibility. Understanding these differences will empower businesses and creators to make well-informed decisions that align with their specific printing requirements.