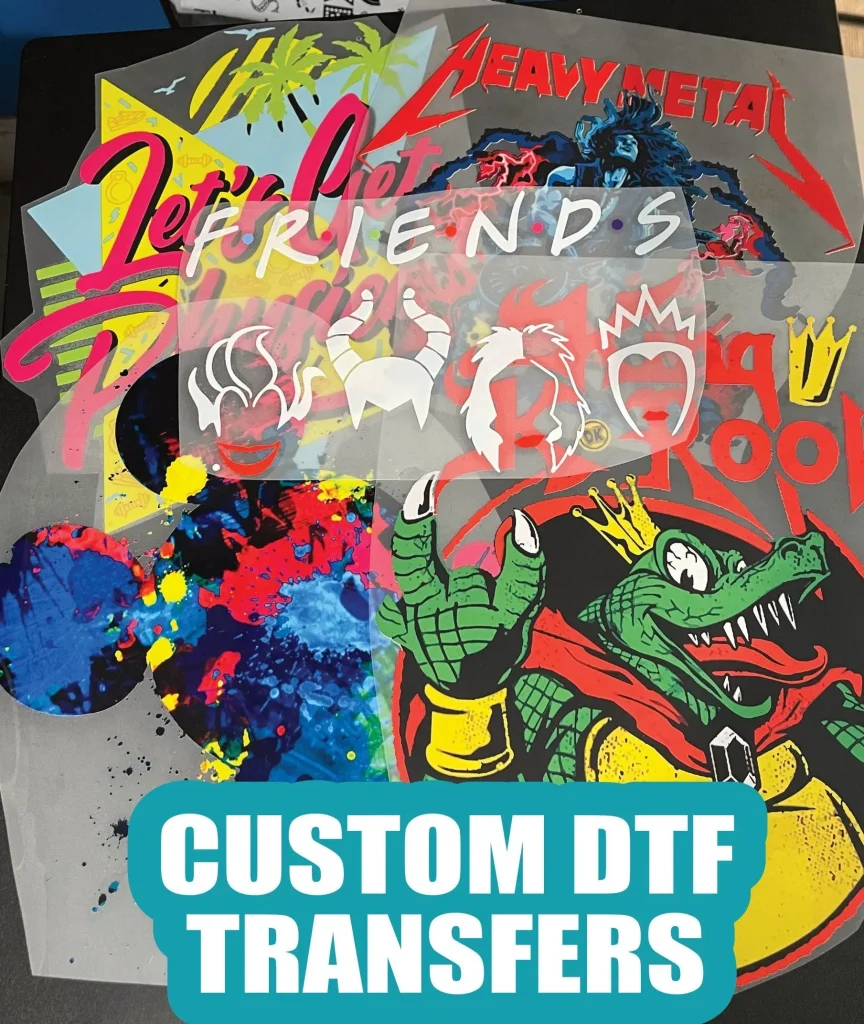

DTF transfers have quickly become a game-changer in the world of custom garment decoration, merging high-quality prints with unmatched versatility. This direct-to-film printing method allows for vibrant and long-lasting designs that cater to various fabric types, making it a preferred choice among professionals and hobbyists alike. However, to truly maximize the potential of DTF transfers, it’s essential to understand key components such as fabric pre-treatment and print quality optimization. In this guide, we will share invaluable DTF printing tips that can help you achieve stunning results every time. Whether you’re a seasoned printer or just starting out, mastering the DTF transfer process will elevate your craft significantly.

Direct-to-Film transfers, often referred to as DTF printing, represent a modern approach to textile printing that has captured the attention of creatives and entrepreneurs across the globe. This innovative technique enables designers to create detailed graphics with excellent color fidelity, making it ideal for a wide range of apparel and accessories. Additionally, the DTF methodology places significant emphasis on crucial preparatory steps, such as fabric pre-treatment, which greatly enhances the final print outcome. As you delve into the nuances of effective transfer methods, understanding the intricacies of print quality optimization will help you maintain high standards in your work. In light of this, let’s explore the essential practices that will ensure your DTF projects are not only visually stunning but also durable.

Understanding the DTF Transfer Process

The DTF transfer process is a innovative method in the world of fabric printing that allows for intricate designs to be applied to garments with relative ease. This process entails printing designs onto a special film, followed by applying adhesive powder and curing it under heat. By distilling the process into clear steps, users can better master each phase, ensuring minimal errors and optimal results. Understanding this process not only streamlines workflow but also emphasizes the importance of precision in each step.

Getting familiar with the DTF transfer process is crucial for achieving vibrant prints. One cannot emphasize enough the necessity of correctly following the specified temperature and time during heat application, as these factors play a significant role in the adhesive properties of the transfer. In addition, being aware of different fabric types and their respective compatibility with the DTF method can further refine your approach, thereby enhancing overall print quality.

Essential Tips for DTF Printing

When it comes to DTF printing, implementing effective tips can drastically improve your results. First and foremost, ensure that your printer is calibrated correctly; this includes adjusting the ink density and print resolution to suit your project’s requirements. Additionally, regular maintenance checks such as cleaning the print head and changing the ink cartridges will help prevent issues that could affect the quality of your prints.

Moreover, paying attention to fabric pre-treatment can considerably elevate the outcome of your DTF transfers. The right pre-treatment solution prepares the fabric, promoting better adhesion and ensuring that the ink bonds effectively to the textile. Without this critical step, printers may experience unwanted challenges, leading to faded or peeling designs.

Print Quality Optimization Techniques

Achieving optimal print quality with DTF transfers is not just about the right ink or film; it’s about understanding the intricate relationship between various elements. Start by ensuring your artwork is high resolution and appropriately sized, as this will significantly affect the clarity and vibrancy of the final product. Utilizing color profiles suited to DTF printing will also enhance the color accuracy and impact of your designs.

In addition, experimenting with different types of transfer films can yield surprising benefits. Films come with diverse properties, and some may work better with your specific inks than others. By taking the time to test various options, you can optimize print quality further, ensuring designs that not only look great but also stand the test of time.

Pre-Treatment and Its Impact on DTF Transfers

Fabric pre-treatment is an often overlooked but critical step in the DTF transfer process. This step not only prepares the fabric surface for better ink adhesion but also maximizes the longevity of the print. Various formulations are available, including spray and dip styles, each suited for different fabric types. Understanding which pre-treatment method aligns best with your chosen textile can lead to substantially improved outcomes.

Moreover, pre-treating your fabric appropriately can help reduce issues like ink bleeding and fading after washes. A well-prepped fabric allows for deeper penetration of the inks, resulting in more vibrant colors and durable designs. Therefore, don’t underestimate the power of fabric pre-treatment; it’s a small step that can produce significant results in your DTF transfer projects.

The Importance of Correct Ink Selection

Selecting the right ink for your DTF printing projects is paramount in ensuring vibrant and long-lasting designs. High-quality pigment-based inks are often recommended since they provide excellent opacity and strong vibrancy on a wide range of fabrics. Using inks specifically designed for DTF applications means that the ink will adhere better to the film and fabric, which translates to better quality transfers.

In addition to color quality, the longevity of printed designs depends heavily on ink choice. Low-quality inks may result in fading after just a few washes, whereas premium inks maintain their vibrancy over time. Taking time to research and invest in high-quality inks is worthwhile and will yield satisfying results in custom garment decoration.

Curing Processes for Durable Transfers

After applying DTF transfers, the curing process is critical for achieving durable and high-quality prints. Proper curing allows the prints to bond firmly with the fabric, ensuring longevity against washing and wear. Utilizing suitable heating tools and ensuring that the temperature is consistently maintained throughout the curing process is essential. A lack of adequate curing can lead to peeling or fading, ultimately compromising the quality of your designs.

Furthermore, consider the time factor during the curing phase, as giving enough time to cool down can increase durability. Rushing through this step can result in poor adhesion and disappointing outcomes. Therefore, ensuring that the transfers are fully cured before washing or using the fabric will significantly enhance the overall print quality, making your DTF transfers look professional and long-lasting.

Frequently Asked Questions

What are the best practices for the DTF transfer process?

To optimize the DTF transfer process, start with proper printer setup, using high-quality DTF films and inks formulated for vibrant color and durability. Ensure correct temperature and pressure during heat transfer, and pre-treat your fabric to enhance ink adhesion. Testing different settings for various fabrics can also lead to improved print quality.

How important is fabric pre-treatment in DTF transfers?

Fabric pre-treatment is crucial for DTF transfers as it prepares the material’s surface for better ink bonding. A suitable pre-treatment solution can improve transfer adhesion, leading to brighter prints that withstand multiple washes. Experimenting with different pre-treatment methods for various fabrics can optimize print quality significantly.

What temperature and pressure settings should I use for DTF printing?

For effective DTF printing, apply the transfer at approximately 385°F (196°C) for 10-15 seconds, using consistent pressure. These settings ensure good ink adhesion and prevent issues like peeling or fading. Investing in a reliable heat press that maintains precise settings is essential for achieving optimal print quality.

What should I consider when selecting inks for DTF printing?

When choosing inks for DTF transfers, opt for high-quality, pigment-based inks specifically designed for DTF applications. These inks provide vibrant colors, excellent opacity, and resistance to fading, ensuring your designs remain striking and durable, even after numerous washes.

How can I improve print quality optimization in DTF transfers?

Improving print quality optimization in DTF transfers involves calibrating your printer correctly, using quality films, and selecting the right inks. Also, maintain consistent temperature and pressure during the heat transfer process and allow adequate curing time for the inks to bond properly with the fabric.

What are some common troubleshooting tips for DTF printing?

To troubleshoot DTF printing issues, check your printer setup for clogging or misalignment, ensure you’re using compatible and high-quality films, and verify that the inks are correctly formulated for DTF use. Additionally, test your temperature and pressure settings, and experiment with fabric pre-treatment methods to enhance adhesion.

| Key Point | Description |

|---|---|

| Proper Printer Setup | Calibrate your DTF printer for optimal performance, including ink density and resolution. Regular maintenance is crucial to prevent clogs and ensure consistent print quality. |

| High-Quality Films | Use films designed for DTF printing with good adhesive properties and surface finish for best transfer quality and durability. |

| Correct Ink Selection | Opt for high-quality, pigment-based inks formulated for DTF applications which offer vibrant colors and excellent fabric compatibility. |

| Temperature and Pressure Control | Maintain precise temperature (around 385°F) and pressure during the heat transfer process to ensure good adhesion of transfers. |

| Pre-Treatment Process | Pre-treat fabrics to create a receptive surface for better ink bonding, enhancing both print quality and durability. |

| Curing of Transfers | Allow sufficient time for transfers to cure after application to secure durability and prevent washout or deterioration. |

| Testing and Adjustments | Regularly test settings on different fabrics and adjust your approach to continuously refine print results. |

Summary

DTF Transfers have revolutionized the world of custom garment decoration, enabling creators to achieve vibrant and durable prints when proper techniques are followed. By focusing on critical aspects such as printer setup, high-quality films, ink selection, temperature control, pre-treatment processes, proper curing, and continuous testing, individuals can significantly enhance the quality of their DTF transfers. Investing in best practices not only maximizes print quality but also ensures longevity in designs, making DTF Transfers a standout choice for those looking to excel in garment printing.