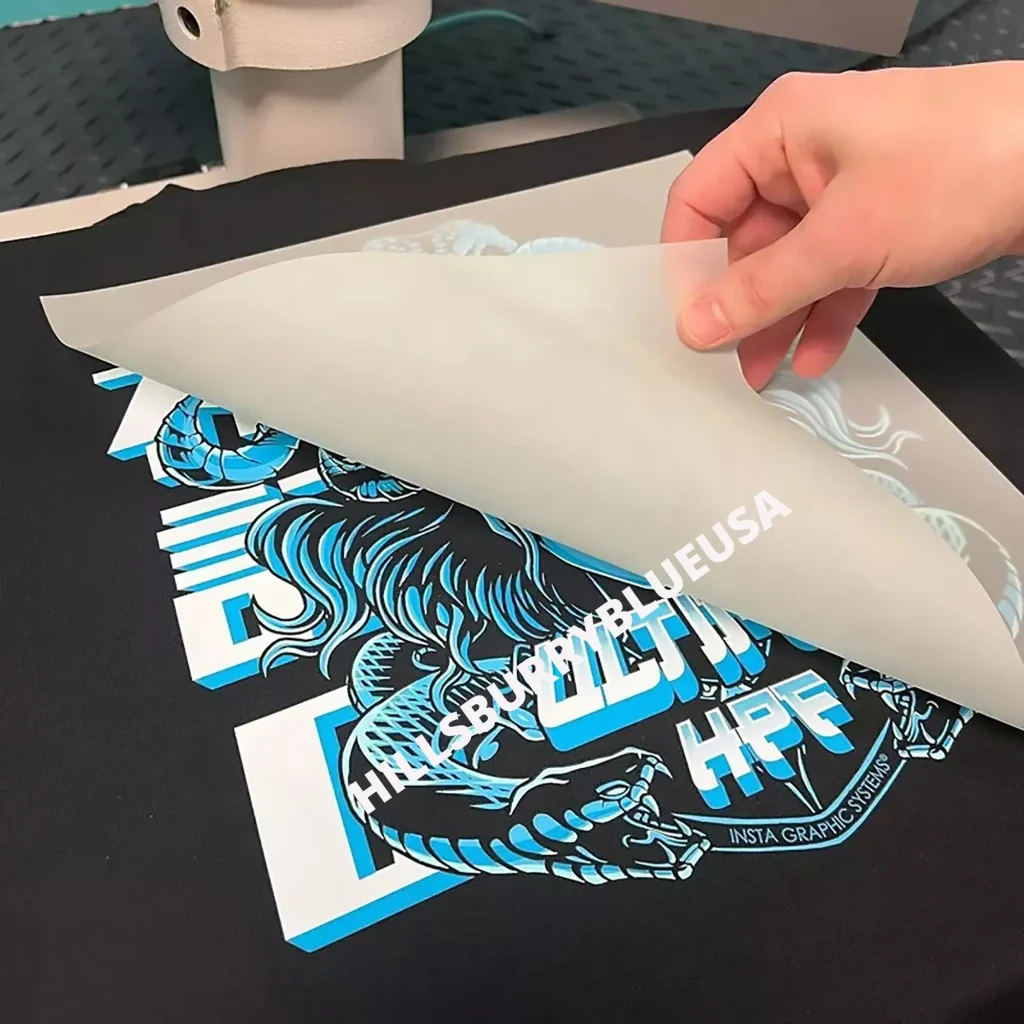

DTF transfers, short for Direct-to-Film transfers, are revolutionizing the world of custom printing with their exceptional versatility and stunning outcomes. This innovative method allows both professional printers and crafting enthusiasts to create visually striking designs that can effortlessly enhance any garment. With the right approach, successful DTF printing can be achieved by following some essential tips, focusing on aspects like DTF design optimization and suitable heat press settings for DTF. Not only do these transfers provide eye-catching results, but they are also designed to stand the test of time with proper post-application care for DTF prints. In this article, we will delve into the best practices for mastering the DTF transfer process, ensuring your creations look fantastic and last long.

In the realm of personalized printing, Direct-to-Film technology is gaining popularity due to its ability to produce bold and vivid imagery on various textiles. Often referred to as DTF printing, this method provides exceptional flexibility for a wide range of applications, allowing creators to apply intricate designs on everything from garments to home decor. As we explore this versatile printing technique, it’s crucial to recognize the significance of key factors such as proper design file preparation and optimizing heat press settings. Additionally, understanding the right care techniques after the application of DTF prints ensures that your designs remain vibrant for years. This article will guide you through the essential strategies for achieving the best outcomes with DTF transfers.

Mastering DTF Design Optimization

Optimizing your designs for Direct-to-Film (DTF) printing is critical for achieving vivid, high-quality results. Start by ensuring that your artwork is appropriately sized and high resolution, as this directly impacts the final print quality. For DTF, using formats like PNG with transparent backgrounds facilitates clear image transfer without any unwanted background interference. Keep in mind that simple designs with clean lines often yield the best results, avoiding intricate details that can become muddled during the print process.

Additionally, consider the color palette of your design. DTF printing excels with vibrant colors, so selecting a well-coordinated color scheme can enhance the visual appeal of your transfers. Familiarize yourself with color theory, and use contrasting shades to make elements stand out. Lastly, conducting color tests can help you find the perfect balance and ensure your designs breathe life into the fabrics, showcasing the full potential of DTF technology.

Key Tips for Successful DTF Printing

To achieve successful DTF printing, it’s essential to follow a structured approach throughout the process. Begin by investing time in selecting high-quality transfer materials that suit your project’s needs. Reliable brands offer products that not only guarantee vibrant prints but also durability against wear and tear. This investment ensures that your DTF designs maintain their original charm, even after numerous washes.

Another vital aspect to consider is the printing method itself. Use a printer that is compatible with DTF transfers and maintain it regularly to avoid any printing couldiness. Clean print heads and proper maintenance can prevent common issues like streaks or faded colors, ensuring consistent quality across multiple prints. By marrying quality materials with meticulous printing techniques, you pave the way for outstanding DTF transfer outcomes.

Understanding Heat Press Settings for DTF

Getting the heat press settings right is arguably one of the most crucial factors in the success of DTF transfers. The typical temperature range of around 325°F (163°C) combined with appropriate pressure is optimal for ensuring a solid bond between the transfer and fabric. It’s important to confirm these settings with the manufacturer’s guidelines, as different types of transfers may require variations in time and temperature for optimal results.

Before running multiple prints, always conduct a test press. This allows you to gauge how the specific fabric reacts to the transfer process, ensuring the press settings yield the desired outcome. Factors such as the fabric’s composition and thickness can affect adhesion, so adjustments may be necessary for different materials. Mastering heat press techniques can significantly elevate the quality and longevity of your DTF prints.

Post-Application Care for DTF Prints

After successfully applying DTF prints, proper care is essential to prolong their lifespan. Encourage customers to follow washing instructions, typically recommending inside-out washing in cold water to preserve colors and prevent fading. Avoid using bleach or fabric softeners, as these can degrade the print quality and durability over time. Educating users on the best care practices not only enhances their printed items’ appearance but also reinforces your commitment to quality.

Moreover, suggest air drying rather than using a dryer, as excessive heat during drying can compromise the integrity of the DTF print. If ironing is needed, recommend placing a cloth over the print to protect it from direct heat. By advocating for proper post-application care, you help customers enjoy their vibrant DTF designs for much longer, leading to higher satisfaction and loyalty.

Innovative Techniques for DTF Transfers

Exploring innovative techniques in DTF transfers can significantly enhance your printing results. One method that has gained traction is layering transfers, where multiple DTF prints are applied to create depth and dimension in a design. This technique not only adds a unique aesthetic touch but allows for a broader range of color combinations and textures. When layering, ensure to adjust your heat settings to avoid scorching the lower layers.

Another exciting technique is using special effects like glitter or metallic finishes on DTF transfers. These effects can elevate the visual appeal of your designs and attract more customers. When engaging with innovative methods, always conduct tests to calibrate your settings accordingly to avoid ruining the transfer. By continually experimenting with different techniques, you can stay ahead in the ever-evolving landscape of DTF printing.

Troubleshooting Common DTF Printing Issues

Even with all precautions, DTF printing may pose some challenges. One common issue is poor adhesion, which can stem from insufficient heat or pressure during the transfer application. In such cases, reviewing heat press settings is crucial to ensure they’re correctly calibrated. It may also help to check the quality of the transfer film, as using subpar products can lead to unsatisfactory results.

Another frequent challenge is color discrepancies between the digital design and the final print. This can usually be mitigated by utilizing an ICC color profile specific to DTF printing. By profiling your printer and settings, you can achieve more consistent color outputs. Additionally, always perform test prints and adjust designs based on actual color outputs, ensuring what you envision matches the end results.

Frequently Asked Questions

What are the essential tips for successful DTF transfers?

Successful DTF transfers hinge on a few key factors. First, ensure you’re using high-quality DTF transfers that deliver vibrant colors and durability. Secondly, prepare your design files meticulously; high-resolution images, preferably in RGB format, will yield the best results. Third, optimize your heat press settings; generally, a temperature of 325°F (163°C) for 15-20 seconds is ideal. Finally, always adhere to post-application care for DTF prints, such as waiting 24 hours before washing to enhance longevity.

How do I optimize designs for DTF transfers?

DTF design optimization involves creating high-resolution images and using vector file formats whenever possible. Vector graphics maintain clarity regardless of scaling. Additionally, avoid overly complex designs that may complicate transfer accuracy. Make sure to use transparent backgrounds in formats like PNG, which are best suited for successful DTF printing.

What heat press settings are recommended for DTF transfers?

For optimal results with DTF transfers, set your heat press to approximately 325°F (163°C) and apply for 15-20 seconds. Ensure even pressure across the transfer and be mindful of specific instructions provided by your transfer supplier, as different products may have slight variations in temperature and pressing time.

What should I consider for post-application care for DTF prints?

Post-application care for DTF prints is essential to maintain their vibrancy and durability. After applying the transfer, allow the garment to rest for 24 hours before washing. When washing, turn the garment inside out and use cold water, avoiding bleach to prolong the life of the print. Always air dry or use a low heat setting in the dryer to prevent damage.

How can I choose high-quality DTF transfers?

To choose high-quality DTF transfers, research reputable brands known for their consistent results and performance. Look for reviews and feedback from other users in the printing community. High-quality transfers will generally offer vibrant colors and resilience under various conditions, ensuring they last longer than lower-quality alternatives.

What are the common mistakes to avoid when using DTF transfers?

Common mistakes in using DTF transfers include utilizing low-resolution images that can lead to poor print quality, neglecting heat press settings which can result in incomplete adherence, and failing to follow post-application care instructions which can damage the print early. Always test on similar fabric before proceeding with a bulk print to avoid costly errors.

| Tip | Description |

|---|---|

| 1. Choose High-Quality Transfers | Ensure vibrant colors and longevity by selecting reputable brands. |

| 2. Ensure Proper Design Files | Use high-resolution PNG or vector files for maximum detail and flexibility. |

| 3. Optimize Heat Press Settings | Set temperatures around 325°F for 15-20 seconds, following supplier instructions closely. |

Summary

DTF transfers have revolutionized the way custom designs are applied to fabrics, offering a combination of durability and vibrancy that appeals to both professionals and hobbyists. By following the essential tips for DTF transfers, such as selecting high-quality materials, ensuring the precision of your design files, and optimizing your heat press settings, you can achieve stunning results that are not only visually striking but also long-lasting. Embracing DTF transfers in your apparel production can elevate your brand’s offerings, providing a competitive edge in the ever-evolving printing market.