In the ever-evolving world of custom apparel, DTF transfers have emerged as a revolutionary printing method that is reshaping how we think about t-shirt printing. This innovative technique, which stands for Direct to Film, offers a unique way to achieve vibrant designs on a variety of fabrics, making it an ideal choice for both small businesses and creative individuals. With the increasing popularity of DTF printing, it’s important to understand its advantages over traditional methods like heat transfer printing and sublimation. Whether you’re looking to create stunning graphics for your brand or personal projects, DTF transfers bridge the gap between high-quality output and affordability. Dive into our comprehensive exploration of why DTF transfers are considered the ultimate choice for t-shirt printing and how they compare to other t-shirt printing methods.

Direct-to-film printing offers a fresh approach to transferring designs onto textiles, standing out as a leading solution in the custom apparel industry. This method harnesses cutting-edge technology to produce high-quality outputs that cater to a diverse range of fabric types, significantly enhancing the customization capabilities for t-shirt designs. When examining printing techniques, DTF becomes a strong contender, especially when compared to alternatives like sublimation or traditional heat transfer methods. Its flexibility and ease of use not only appeal to professional businesses but also to hobbyists and crafters eager to experiment with their creative ideas. As we delve deeper into the features and benefits of DTF, it’s essential to understand the industry context and advancements that make this printing method a top choice.

Understanding DTF Printing Technology

DTF printing technology, or Direct to Film printing, has significantly transformed the custom apparel landscape in recent years. This innovative process involves printing designs onto a flexible film that can then be transferred to a variety of textiles using heat and pressure. As a result, DTF transfers are increasingly popular among both small creators and large apparel brands, thanks to their ability to produce high-quality prints quickly and efficiently.

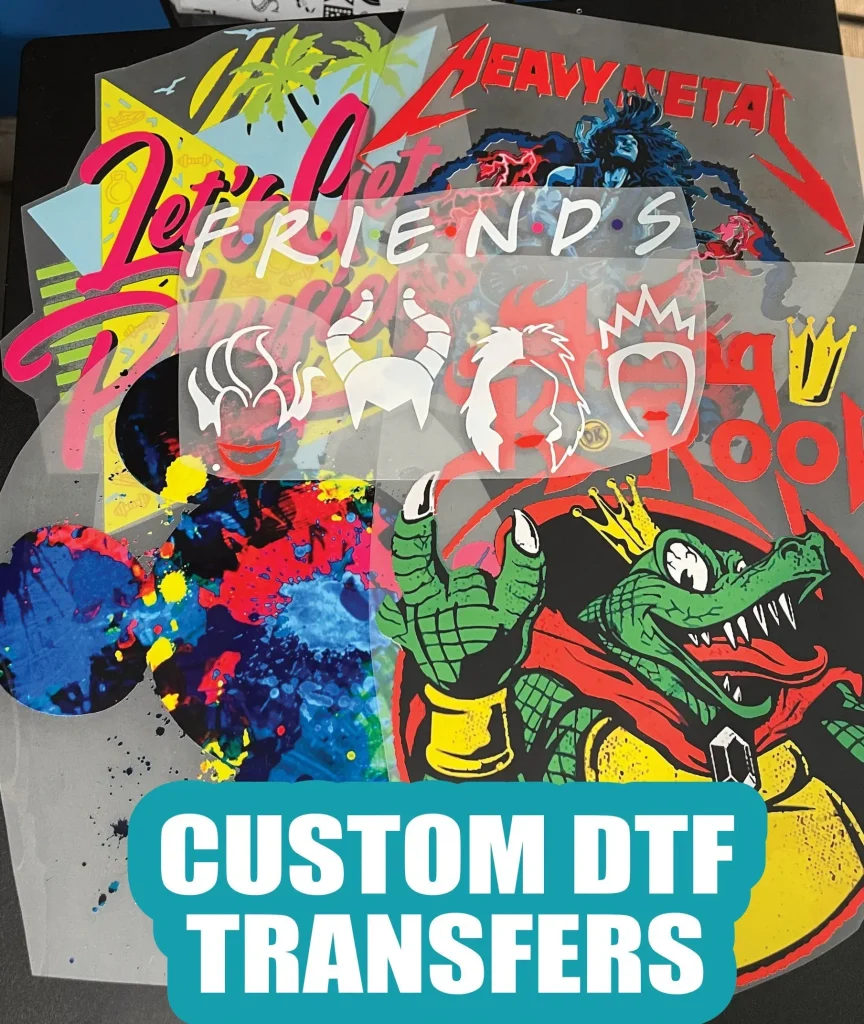

One of the standout features of DTF technology is its capacity to print vibrant, full-color designs that can adhere to numerous fabric types, including cotton, polyester, and blends. This versatility makes DTF a preferred choice compared to other methods, as it accommodates different design needs and fabric combinations, opening up new possibilities for creative expression in the world of custom t-shirt printing.

The Rise of DTF Transfers in Custom Apparel

In recent years, DTF transfers have established themselves as a leader in the custom apparel market, particularly among small businesses and individual creators who value accessible and personalized options. Companies such as Sam’s DTF Transfers have started offering high-quality transfer services with no minimum order requirements, making it easier for entrepreneurs and designers to create unique apparel without upfront costs.

This shift towards DTF printing reflects a broader trend towards customization and personalization in fashion. As consumers gravitate towards unique, curated styles, the demand for adaptable printing solutions like DTF transfers continues to grow, solidifying their place as the ultimate choice for t-shirt printing in the current market.

Quality and Durability of DTF Transfers

One of the main advantages of DTF transfers is their excellent quality and durability. The prints produced through this method are not only vibrant and eye-catching but also withstand the test of time. Users report that DTF prints hold their color vibrancy even after repeated washes, making them an ideal choice for everyday apparel and custom merchandise alike.

The durability of DTF transfers is particularly essential for businesses looking to maintain quality in their products. Brands can assure customers that the logos and designs featured on their clothing will remain intact and visually appealing over time, which is a crucial factor in customer satisfaction and brand loyalty in the competitive custom apparel market.

DTF Transfers vs. Other Printing Techniques

When comparing DTF transfers to traditional printing techniques like sublimation or screen printing, the benefits of DTF become quite evident. Unlike sublimation, which only works on synthetic fabrics, DTF transfers can effectively be used on various fabric types, including natural materials such as cotton and dark fabrics—a significant advantage for designers looking for versatility.

Moreover, while screen printing may require significant setup for multiple colors, DTF simplifies the process by allowing high-quality full-color designs without the cumbersome setup. This efficiency and adaptability highlight why DTF transfers are becoming the preferred printing method for many in the apparel industry.

The Customization Revolution with DTF Transfers

DTF transfers embody the customization revolution sweeping through the apparel industry. With platforms like DTFPrinter catering specifically to hobbyists and small-scale creators, the barriers to producing high-quality, customized apparel have never been lower. Users can easily create custom designs that can be printed on demand, ensuring that they can offer unique pieces that resonate with their target audience.

This accessibility and usability empower users to experiment with their designs and maximize their creative opportunities. The ability to produce professional-quality full-color transfers allows both seasoned designers and newcomers to explore their artistic potential in the world of custom t-shirt printing.

Cost-Effectiveness of DTF Transfers

Another compelling reason for the rising popularity of DTF transfers is their cost-effectiveness. Businesses, especially startups, can significantly reduce their expenses by eliminating the need for minimum order quantities. Companies like Sam’s DTF Transfers offer services that allow users to order only what they need, lowering the financial barriers associated with inventory management.

This flexibility encourages experimentation and creativity, enabling businesses to test new designs and styles without financial risk. In a market where consumers demand variety and personalization, DTF transfers provide the perfect solution for entrepreneurs looking to innovate while also streamlining their costs.

Frequently Asked Questions

What are the benefits of using DTF Transfers for custom apparel?

DTF transfers offer numerous benefits, such as exceptional quality and durability, vibrant colors, versatility to print on various materials, ease of use for beginners, and cost-effectiveness with no minimum order requirements, making them an ideal choice for custom apparel.

How do DTF Transfers compare to traditional t-shirt printing methods?

When compared to traditional methods like screen printing or sublimation, DTF transfers stand out due to their versatility, as they can be applied to a variety of fabrics including cotton and dark materials, whereas sublimation is limited to synthetic textiles. This makes DTF a more flexible option for custom t-shirt printing.

What materials can I use with DTF Transfers?

DTF transfers are highly versatile and can be used on a range of materials, including cotton, polyester, blends, and even leather. This flexibility allows for extensive creativity in custom apparel designs.

How do I apply DTF Transfers to my garments?

Applying DTF transfers involves printing your design onto a film, coating it with adhesive powder, and curing it with heat. Then, using a heat press, you can transfer the design onto your garment. This straightforward process makes DTF printing accessible for both DIY enthusiasts and commercial applications.

Are DTF transfers more cost-effective than other printing techniques?

Yes, DTF transfers can be more cost-effective, especially since many providers like Sam’s DTF Transfers offer no minimum order requirements. This allows businesses and creators to order only what they need, minimizing waste and financial risk compared to bulk orders in other printing methods.

What advancements are being made in DTF printing technology?

Recent advancements in DTF printing technology include the introduction of high-quality, durable DTF heat transfers by companies like Insta Graphic Systems, enhancing print vibrancy and longevity. Such developments are key to ensuring high standards in custom apparel printing and addressing customer expectations.

| Key Point | Details |

|---|---|

| Introduction | DTF transfers are a revolutionary printing method in custom apparel, offering advanced technology and diverse fabric compatibility. |

| What are DTF Transfers? | DTF transfers use a specialized film to print designs onto various materials through a heat transfer process. |

| Key Developments | Emergence of premium services, technological innovations, versatility compared to other techniques, and enhanced customization options. |

| Benefits of DTF Transfers | Superior quality & durability, versatility in fabric choice, ease of use, and cost-effectiveness. |

Summary

DTF Transfers are revolutionizing the t-shirt printing landscape, marking themselves as the ultimate choice for those seeking high-quality and customizable apparel. The significant advancements in technology, coupled with the rise of premium services, give both small businesses and individual creators unprecedented access to durable and vibrant prints. DTF’s versatility allows it to cater to a wide array of fabrics, enabling creativity at every level. Furthermore, its user-friendliness makes it an attractive option for newcomers to custom shirt printing. The future of apparel customization looks promising with DTF Transfers leading the charge, guaranteeing reliability and innovation in the industry.