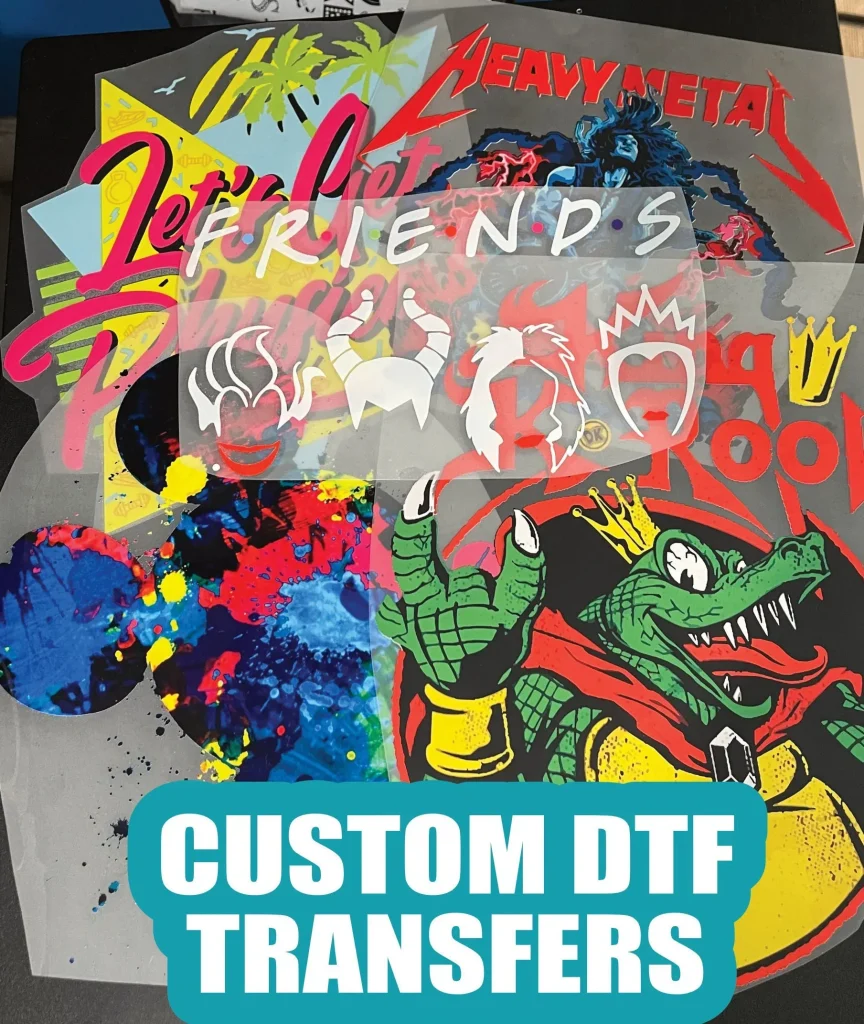

DTF transfers, or Direct-to-Film transfers, represent a revolutionary advancement in t-shirt printing technology that is capturing the attention of businesses and consumers alike. This innovative method allows for vibrant, high-definition designs to be transferred onto a variety of fabrics, making it an ideal choice for custom t-shirt printing projects. With its cost-effective approach, DTF technology significantly reduces overhead costs compared to traditional methods like screen printing, making it accessible for startups and established companies alike. Moreover, the use of water-based inks in DTF printing supports sustainable apparel production, appealing to environmentally-conscious customers. As the demand for personalized and unique designs grows, DTF transfers are set to redefine the landscape of the garment industry.

Also known as direct-to-film printing, DTF printing technology has emerged as a leading option for business owners seeking diverse and compelling apparel solutions. By utilizing advanced printing methods, this technique enables high-resolution images to be easily applied to a variety of garment types, from t-shirts to hoodies and beyond. The balance of efficiency and quality not only satisfies consumer desires for customization but also supports sustainable practices within the apparel production sector. Businesses leveraging this innovative printing process can avoid the heavy costs associated with traditional printing setups, leading to better profit margins and enhanced product diversity. Ultimately, the versatility and ease of application offered by DTF transfers position them as a favored choice in today’s competitive market.

The Rise of DTF Printing Technology

Direct-to-Film (DTF) printing technology has significantly transformed the t-shirt printing landscape, providing an innovative solution that marries artistic expression with practical production. As businesses strive for unique offerings in a crowded marketplace, DTF transfers have emerged as a preferred choice due to their ability to produce high-definition designs on a variety of fabrics. This advanced printing method utilizes specialized inks and films that allow for intricate and colorful prints that stand out, putting the creative capabilities of designers at the forefront.

Moreover, advancements in DTF technology have streamlined the printing process, rendering it more efficient than traditional methods. The shift from screen printing to DTF has enabled companies to maintain pace with market demands while ensuring high-quality output. Businesses are now able to cater to a growing demand for customized apparel without the heavy logistical burdens that used to accompany large-scale printing jobs. Thus, with the integration of DTF printing technology, the industry has paved the way for a bright future in textile production.

Cost-Effective Custom T-Shirt Printing Solutions

In the competitive world of custom t-shirt printing, cost-effective solutions are vital for business sustainability. DTF transfers present a breakthrough in affordability compared to traditional screen printing techniques, which often require substantial initial investments in equipment and setup. With DTF printing, businesses can eliminate these extensive costs by directly applying designs onto films, creating a streamlined, budget-friendly production process that appeals to small and medium-sized enterprises.

This cost-effectiveness extends beyond initial investments; it also facilitates rapid production cycles and reduces material waste, making it an ideal solution for businesses looking to manage expenses. Startups can leverage DTF transfers to enter the market with reduced financial risk, capitalize on custom orders, and cultivate customer loyalty through unique products. As a result, DTF printing is not just a trend; it is a sagacious choice that empowers businesses to focus on innovation and growth.

In addition, the adaptable nature of DTF transfers means that companies can diversify their offerings without incurring prohibitive costs. With the ability to print on various fabrics, it opens up avenues for businesses to explore different product lines, maintaining flexibility in their business model.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve a printing process where designs are printed onto a special film and then transferred onto garments using heat. This innovative method utilizes high-quality inks to produce vibrant, long-lasting prints that can decorate a variety of fabrics, including cotton and polyester.

Why should I consider DTF printing technology for custom t-shirt printing?

DTF printing technology is ideal for custom t-shirt printing because it allows for high-resolution images with intricate details and a wide range of colors. This flexibility ensures that businesses can meet diverse customer demands for unique designs without the typical limitations found in traditional printing methods.

How is DTF transfers cost-effective compared to other printing methods?

DTF transfers are cost-effective as they eliminate the high setup costs associated with screen printing. With DTF printing, businesses can print directly on film without extensive initial investments, making it an excellent choice for small to medium enterprises looking to enter the custom apparel market.

Are DTF transfers a sustainable option for apparel production?

Yes, DTF transfers are considered a sustainable option as they use water-based inks that are less harmful to the environment compared to traditional solvent-based inks. Additionally, DTF printing generates less waste, aligning well with the increasing consumer demand for eco-friendly apparel production.

What types of garments can benefit from DTF transfers?

DTF transfers can be applied to a wide variety of garments, including t-shirts, hoodies, bags, and more. The versatility of DTF printing allows producers to expand their offerings across different fabrics and products, catering to a broader customer base.

How can businesses leverage the advantages of DTF printing to enhance customer satisfaction?

Businesses can leverage DTF printing by offering personalized and unique products with quick turnaround times. By employing DTF transfers, companies can meet the growing consumer demand for customization while also providing high-quality, durable prints that enhance customer satisfaction and loyalty.

| Key Point | Description |

|---|---|

| Advancements in Technology | DTF printing achieves higher resolution designs with vibrant colors, surpassing traditional screen printing methods. |

| Cost-Effectiveness | Reduced initial setup costs make DTF suitable for small to medium enterprises, offering a creative solution without high investments. |

| Sustainability | Utilizes environmentally friendly inks and generates less waste, appealing to eco-conscious consumers. |

| Versatility and Ease of Use | DTF can be applied to various materials, allowing businesses to produce a wide range of custom products. |

| Market Growth and Adoption | Increasing demand for personalized and on-demand services drives the growth of DTF printing in the industry. |

Summary

DTF transfers are revolutionizing the t-shirt printing industry by offering a modern solution that combines quality, efficiency, and sustainability. As technology continues to advance, DTF transfers allow businesses to create unique and vibrant designs with ease, catering to a growing demand for custom and eco-friendly apparel. By effectively reducing costs and waste, and by providing versatility in applications across various fabrics, DTF transfers empower both established businesses and startups to thrive in a competitive market. With an upward trend in market adoption, the future of t-shirt printing is indeed intertwined with the advantages offered by DTF transfers.