Direct to Film transfers, commonly known as DTF transfers, are revolutionizing the printing industry by providing a versatile and cost-effective solution for custom apparel printing. Unlike traditional methods, DTF printing utilizes innovative digital printing technology to deliver vibrant, high-quality prints on various fabric types. This technique not only caters to the growing demand for personalized clothing but also aligns with sustainable printing practices by minimizing waste and using eco-friendly inks. As businesses and consumers increasingly seek out cost-effective printing solutions, the appeal of DTF transfers continues to rise. This blog post delves deeper into the benefits and future potential of this cutting-edge printing method.

The emergence of Direct to Film printing technology heralds a new era in custom textile decoration, paving the way for fresh, innovative approaches to printing. This method, often referred to as DTF printing, employs advanced digital techniques to produce high-quality images directly onto film, which can then be transferred onto a variety of materials. Given its adaptability, this printing process is capturing the attention of artists and entrepreneurs looking to break into the custom apparel market. The incorporation of sustainable printing methods into DTF practices enhances its appeal, especially among environmentally conscious consumers. With its numerous benefits and applications, DTF technology is set to reshape the landscape of the printing industry.

The Versatility of DTF Transfers in Custom Apparel

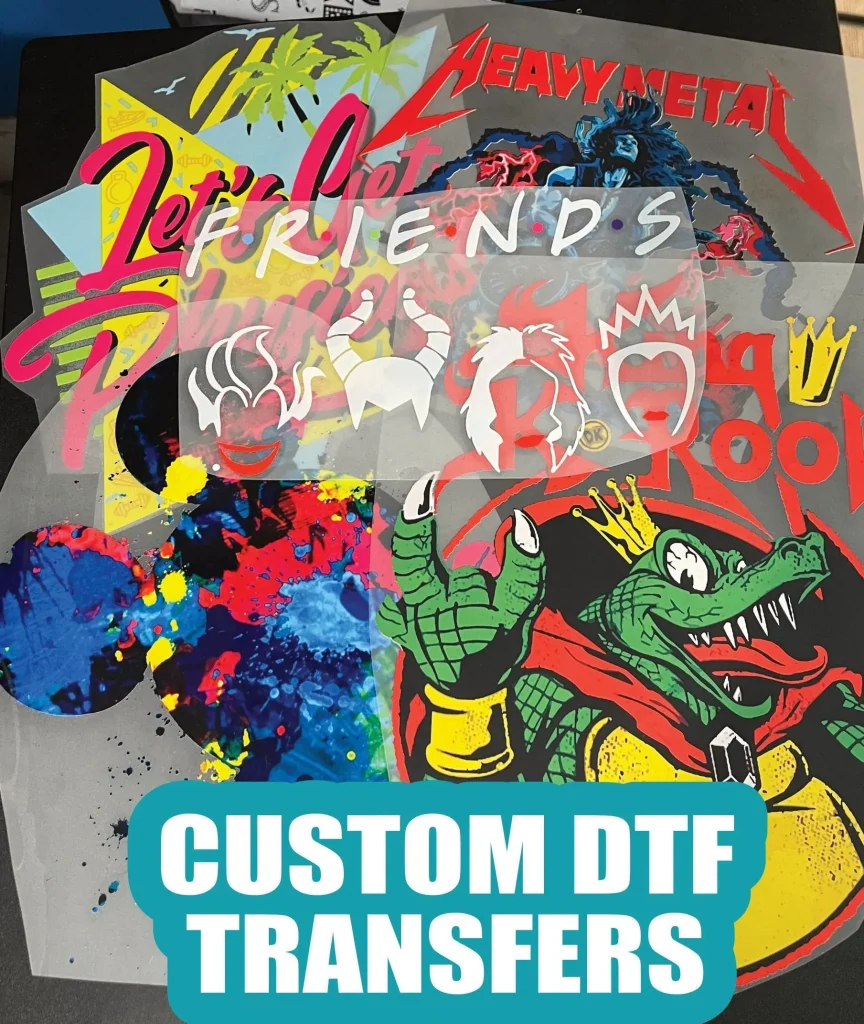

Direct to Film (DTF) transfers have revolutionized the custom apparel printing industry, offering unparalleled flexibility and adaptability. This printing technique allows for vibrant and detailed designs on a variety of fabrics, including both natural and synthetic materials. Unlike traditional methods such as screen printing, which often require specific types of fabrics and colors, DTF transfers can handle complex and colorful designs with ease. This versatility opens doors for businesses to cater to diverse consumer preferences, allowing for unique, personalized garments that stand out in a crowded market.

Moreover, DTF technology provides an efficient solution for small businesses looking to enter the custom apparel space. Whether for limited runs or mass production, DTF printing enables businesses to produce high-quality designs without the significant setup costs associated with screen printing. The ease with which designs can be manipulated digitally ensures that brands can stay current with trends, respond to customer feedback, and maintain a fresh product line with minimal hassle.

Cost Benefits of DTF Printing

One of the most compelling aspects of DTF transfers is their cost-effectiveness for both startups and established businesses. The initial investment required for DTF printing technology is significantly lower than that of traditional printing methods. This democratization of printing allows entrepreneurs to harness high-quality printing without breaking the bank. Alongside reduced equipment costs, the minimal consumable expenses associated with DTF printing further enhance its appeal, providing a sustainable financial model for businesses looking to thrive in a competitive landscape.

In addition to lower startup costs, DTF printing also streamlines the production process, cutting down on labor and time expenses. By utilizing advanced digital printing technology, businesses can quickly produce prints with precision and reliability. This efficiency translates into faster turnaround times for custom orders and the ability to respond swiftly to market demands, giving businesses an edge against competitors who may still rely on more traditional and slower printing methods.

Advancements in DTF Technology

As the printing industry continues to evolve, technological advancements are paving the way for superior DTF printing capabilities. Newer models of DTF printers are equipped with cutting-edge features that enhance speed, quality, and durability of the printed products. These innovations ensure that businesses can keep up with increasing consumer expectations for higher quality prints without compromising on production timelines.

The advancement of digital printing technology also means that the detail and vibrancy achieved through DTF printing are constantly improving. Innovations in ink formulations have led to a wider color gamut and improved adhesion to various fabric types, pushing the boundaries of what can be achieved in custom designs. This not only fortifies the market position of DTF transfers but also encourages businesses to explore new design possibilities, further expanding their creativity and product offerings.

Sustainability in DTF Printing Practices

With increasing consumer awareness around environmental issues, DTF printing stands out as a sustainable option within the printing industry. Utilizing water-based inks, DTF transfers significantly reduce the environmental impact compared to traditional printing methods that rely on toxic chemicals. This environmentally friendly approach appeals to businesses and consumers alike who are committed to sustainable practices and products.

Beyond the ink used, the DTF printing process itself results in less waste, aligning closely with the principles of sustainable printing practices. By minimizing overproduction and offering print-on-demand solutions, DTF technology empowers businesses to operate more responsibly while still meeting custom printing demands. As a result, companies embracing DTF printing can enhance their brand image and attract environmentally conscious customers.

Expanding Applications of DTF Technology

DTF printing is not just limited to custom apparel; its applications are rapidly expanding into various industries, allowing businesses to diversify their offerings. From home décor items like printed cushion covers to promotional products such as banners and gift items, the flexibility of DTF technology has opened new markets for creative entrepreneurs. This broader application helps businesses tap into new revenue streams and cater to different customer segments.

As more industries recognize the advantages of DTF transfers, the printing landscape is continuously adapting. Companies are increasingly utilizing DTF technology for signage and promotional materials, broadening the scope of what businesses can create and present to their clients. With a unique edge in decoration and branding, DTF printing positions itself as a long-term fixture in various sectors beyond traditional garment printing.

Industry Sentiment and Future Trends

The prevailing sentiment among industry experts is that DTF transfers represent a significant shift within the digital printing landscape, marking a shift towards more personalized, on-demand production. Businesses are beginning to recognize the benefits of producing small runs economically, which aligns perfectly with shifting consumer preferences for customized and unique products. As demand for personalized items continues to rise, DTF printing places companies in a prime position to succeed.

In addition, the ability to cater to niche markets through cost-effective solutions makes DTF transfers particularly attractive in today’s economy. As consumers increasingly seek unique products tailored to their needs, businesses that adopt DTF printing are not only keeping up with trends but are poised to lead in the evolving printing industry. The combination of innovation with consumer-centric approaches solidifies DTF technology as a crucial component of future printing strategies.

Frequently Asked Questions

What are DTF transfers and how do they differ from traditional printing methods?

DTF transfers, or Direct to Film transfers, are a modern printing technique that allows high-quality prints on various fabrics such as cotton and polyester. Unlike traditional methods like screen printing, DTF offers greater flexibility and is cost-effective, making it ideal for custom apparel printing. The process involves printing designs onto a special film and then transferring them onto the fabric using heat, resulting in vibrant and durable prints.

How does DTF printing contribute to sustainable printing practices?

DTF printing promotes sustainable printing practices by utilizing water-based inks, significantly reducing harmful waste compared to conventional methods. Additionally, DTF transfers generate less material waste during production, making them a greener choice for businesses aiming to minimize their environmental impact. By aligning with eco-friendly operations, companies can meet consumer expectations for sustainable products.

Are DTF transfers a cost-effective solution for custom apparel printing?

Yes, DTF transfers are considered a cost-effective solution for custom apparel printing. The initial investment required for DTF printing equipment is typically lower than that for traditional methods like screen printing. This makes it accessible for small businesses and print shops, allowing them to offer competitive pricing while maintaining high print quality.

What industries are benefiting from the expanding applications of DTF printing?

DTF printing is gaining traction beyond custom apparel and is being adopted in various industries, including home decor, promotional products, and signage. As businesses explore new avenues for DTF applications, they find that its versatility makes it a valuable method for a wide range of products, further solidifying its position in the market.

What technological advancements are enhancing DTF transfer production?

Recent technological advancements in DTF printing have led to faster production speeds and improved print quality with enhanced durability and detail. Newer DTF printers are easier to operate, allowing businesses to meet rising consumer demands for high-quality prints efficiently. These innovations are propelling the growth and adoption of DTF printing across small and medium-sized enterprises.

Why are DTF transfers seen as a long-term trend in the digital printing landscape?

Experts view DTF transfers as a long-term trend due to their adaptability and economic benefits in custom printing. The ability to produce small runs and personalized items on demand aligns perfectly with growing consumer preferences. As businesses continue to adopt DTF technology, its practical advantages and sustainability appeal bolster its status as a key player in the evolving digital printing landscape.

| Key Points | Details |

|---|---|

| Introduction | Exploration of DTF transfers as a modern printing alternative. |

| Growth in Popularity | DTF printing’s popularity is surging, especially in custom apparel, due to its versatility and demand. |

| Cost-Effective Production | Lower startup costs attract small businesses, offering competitive pricing. |

| Technological Advancements | Faster printers with enhanced durability and detail boost demand and efficiency. |

| Sustainability Considerations | Water-based inks minimize toxic waste, aligning with eco-friendly practices. |

| Expanding Applications | DTF is branching into home decor, promotional products, and signage. |

| Industry Sentiment | Experts affirm DTF as a robust and lasting fixture in digital printing. |

Summary

DTF transfers are poised to redefine the printing landscape with their innovative approach and benefits. They stand out for their affordability and adaptability in various markets, making them a perfect solution for businesses looking to personalize products efficiently. The ongoing advancements in DTF technology combined with a commitment to sustainable practices cater to the growing consumer demand for environmentally friendly and customized items. As DTF transfers gain further traction across different industries, their role will undoubtedly expand, solidifying their position within the future of printing.