DTF Transfers, or Direct to Film printing, have emerged as a game-changer in the realm of custom apparel printing, offering a modern solution for vibrant and detailed designs. This innovative technology combines efficiency with high-quality output, making it a popular choice among both amateurs and professionals. As the industry evolves, the advantages of DTF printing—such as its versatility across fabrics and cost-effectiveness for small runs—become increasingly apparent. In this blog post, we will delve into the various benefits and limitations of DTF Transfers compared to other methods like Direct to Garment (DTG) printing and traditional screen printing, highlighting why many are choosing this route. Equip yourself with insights on DTF vs DTG and discover how to make informed choices for your printing needs.

Direct to Film transfers represent a cutting-edge approach within the broad spectrum of garment printing techniques. Often contrasted with styles like Direct to Garment applications or conventional screen printing, DTF offers distinct perks that appeal to a diverse range of creators. The efficiency and quality of DTF printing not only enable the transfer of vibrant designs but also cater to various fabric types, standing apart from other methods that may impose limitations. As we analyze the various printing alternatives, including the comparisons between heat transfer vinyl and screen printing drawbacks, it’s essential to understand how DTF can fulfill unique production requirements effectively.

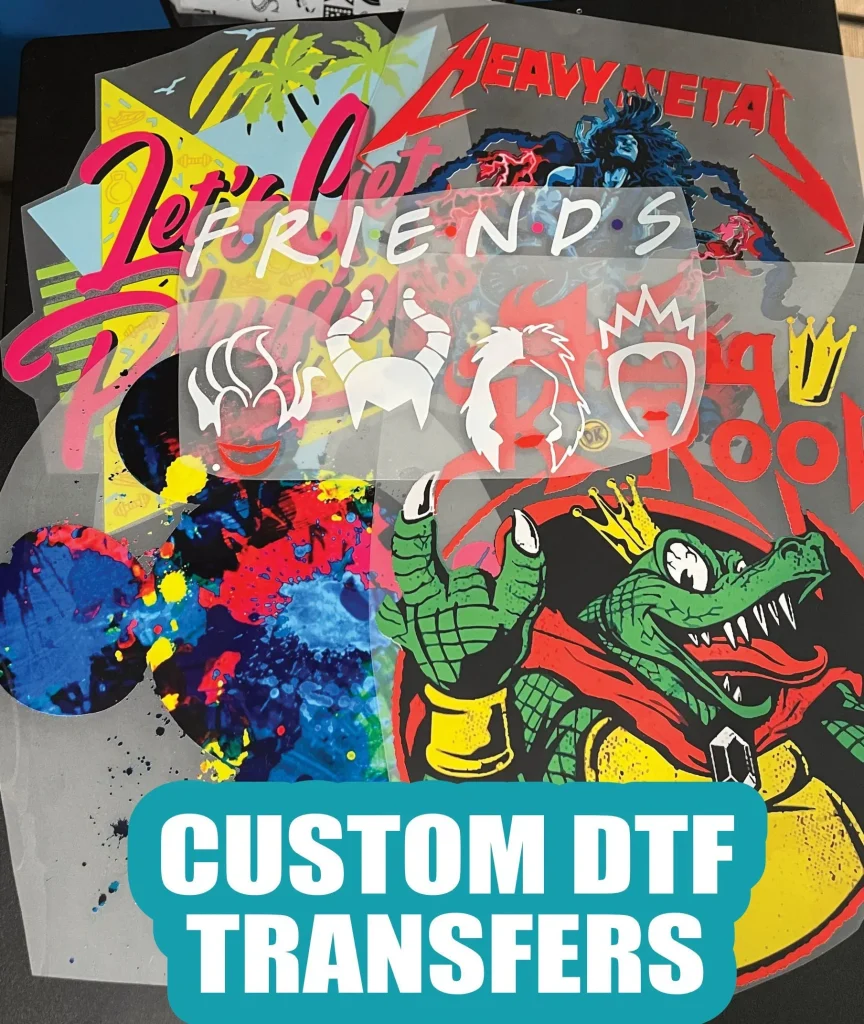

The Advantages of DTF Printing Over Traditional Methods

One of the key advantages of DTF transfers is their remarkable versatility across different materials. This method allows printers to apply designs seamlessly to a variety of fabric types, from cotton and polyester to blends that may pose challenges for other printing techniques. In contrast, many traditional methods, such as screen printing, are often limited to specific fabric types, making DTF a more inclusive choice for garment decorators. As a result, businesses can cater to a broader customer base, including those with unique fabric needs.

Moreover, DTF printing is known for its ability to produce vibrant colors and intricate details that really pop on apparel. This is particularly beneficial for businesses looking to stand out with impressive graphics. Unlike screen printing, which can struggle with achieving the same level of detail due to its color limitations, DTF ensures that each design flawlessly retains its intended impact, making garments visually striking even at a close inspection.

DTF vs. Direct to Garment (DTG) Printing

When comparing DTF with Direct to Garment (DTG) printing, certain distinctions become apparent, especially regarding fabric compatibility and production costs. While DTG is excellent for high-detail designs, it typically works best on 100% cotton fabrics. This restriction can limit businesses that wish to print on synthetic or blended fabrics, a gap that DTF printing fills adeptly. Additionally, DTF printing tends to be more cost-effective for smaller orders, as it avoids the intricate setup costs associated with DTG, making it an appealing alternative for custom and low-run projects.

On the other hand, it’s crucial to note that DTG generally produces exceptional color gradients and weaves, which can be an advantage for highly intricate designs. Thus, businesses must evaluate their priorities—if they require flexibility in fabric options and reduced setup times, DTF is the better choice, while DTG might be favored for detailed, high-volume orders of specific fabrics.

Screen Printing vs. DTF: Pros and Cons

Screen printing has long been the industry standard for many print shops, particularly for large batches due to its cost efficiency and robust final results. However, this technique comes with its own set of drawbacks, including prolonged setup times and limitations on the number of colors that can be effectively used in one design. DTF printing acts as a breath of fresh air in this regard; its ability to easily manage multi-colored images without the need for extensive setup is a significant advantage over traditional screen printing.

Additionally, DTF transfers provide similar durability to screen prints while allowing for much finer details. They can withstand washing and wearing with minimal cracking or fading over time, as do many traditional methods, making them a fantastic option for apparel that must stand up to the elements. Thus, for businesses seeking quick turnaround times for versatile and colorful designs, DTF transfers often present an ideal balance of quality and efficiency.

Heat Transfer Vinyl Comparisons: DTF Printing’s Edge

Heat Transfer Vinyl (HTV) is another popular method for custom apparel, known for its straightforward application process, particularly for single-color designs. However, HTV can become increasingly cumbersome when handling multi-colored graphics or intricate details due to manual layering and weeding processes. In this respect, DTF printing offers a significant advantage, streamlining the printing process with the ability to transfer complex, full-color designs in a single step, thereby minimizing labor-intensive tasks.

Moreover, DTF’s adaptability to various fabric types surpasses the limitations of HTV, which may struggle with fabric compatibility issues. For example, while HTV might not adhere well to certain materials, DTF can easily bond with cotton, poly blends, and numerous other fabrics. This versatility makes DTF a more viable option for businesses looking to expand their offerings without compromising on quality or design complexity.

Current Trends in DTF Printing

As we look toward the future of custom apparel, DTF printing is firmly establishing itself as a leading choice within the industry. Increasingly, businesses are embracing this printing method due to its flexibility and high-quality output. The trend is fueled by a growing consumer demand for personalized, high-resolution designs, which DTF readily satisfies. This momentum is expected to continue, especially as advancements in DTF technology lead to even better print quality and faster turnaround times.

In addition to the technical benefits, the rise of eco-conscious practices is influencing the popularity of DTF printing. With manufacturers striving to create more sustainable processes, DTF has the potential to incorporate eco-friendly inks and materials into its workflow. This aligns with the contemporary consumer preference for environmentally responsible products, thus placing DTF printing as not only a practical choice but also a progressive one in the market.

Making Informed Choices for Custom Apparel

Choosing the right printing method for your apparel needs requires careful consideration of several factors, including design complexity, fabric types, and production volume. DTF transfers stand out as an excellent option for those seeking vibrant, multi-colored prints without the extensive setup costs associated with screen printing or DTG methods. For small batch orders and custom creations, DTF may prove to be the most efficient and cost-effective choice.

Additionally, it’s vital for businesses to conduct thorough research on each printing method, weighing the advantages against potential drawbacks. Understanding the nuances of DTF compared to DTG, screen printing, and HTV can empower creators to make choices that align with their artistic vision and operational needs, ensuring successful outcomes that resonate with their target audience.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film printing, utilize a specialized film to transfer designs onto fabrics. The process involves printing the desired image onto the film, applying an adhesive, and then adhering it to the garment using heat and pressure. This technique allows for vibrant, detailed prints on various fabric types.

What are the advantages of DTF printing over traditional methods?

The advantages of DTF printing include versatility across different fabrics, vibrant color reproduction, cost-effectiveness for small runs, and durability of the prints. Unlike screen printing, DTF can handle complex designs without color limitations, making it a popular choice for custom apparel.

How does DTF printing compare to DTG printing?

DTF vs DTG reveals that while both methods offer high-detail prints, DTF transfers provide more versatility in fabric options and are often more cost-effective for small batches. DTG tends to have a higher initial cost and may restrict fabric choices compared to DTF.

What are the drawbacks of screen printing compared to DTF transfers?

Screen printing drawbacks include extensive setup time and limitations in color options, which can hinder creative designs. In contrast, DTF transfers support multi-colored images without additional separations and are more efficient for small orders.

How do DTF Transfers compare with heat transfer vinyl (HTV)?

When making heat transfer vinyl comparisons with DTF transfers, it becomes clear that DTF is superior for multi-colored designs. HTV is generally suited for simpler designs and can be labor-intensive, while DTF offers greater creativity and efficiency for detailed prints.

What should I consider when choosing DTF Transfers for custom printing?

When considering DTF transfers for custom printing, evaluate the initial equipment costs, the learning curve associated with the process, and your specific production needs. Understanding the pros and cons compared to methods like screen printing and DTG will help in making an informed decision.

| Aspect | DTF Transfers | Pros | Cons | Comparison with Other Methods |

|---|---|---|---|---|

| Versatility | Applies to various fabrics like cotton and polyester | Highly versatile across fabric types | Higher initial equipment costs | More versatile than DTG and HTV, which have fabric limitations. |

| Vibrancy and Detail | Produces high-resolution images with intricate designs | Vibrant color reproduction and complex graphics | Production speed may be slower for larger orders | Outperforms screen printing in terms of design complexity and colors. |

| Cost-Effectiveness | Lower costs for small runs compared to screen printing | Ideal for custom prints without setup costs | Learning curve involved for new users | More economical for small orders than screen printing. |

| Durability | Minimal cracking and fading over time | Lasting quality similar to screen prints | Dependence on adhesive powder for production | Equal to screen printing in durability but more complex due to adhesive. |

| Color Limitations | Supports multi-colored designs easily | No additional color separations needed | Requires specific adhesives | More flexible with colors compared to screen printing and HTV. |

Summary

DTF Transfers represent a significant advancement in the custom apparel printing industry, providing creativity and flexibility to designers and brands. The method allows for vibrant and detailed prints on a wide array of fabrics, making it a viable choice for many businesses. While DTF printing comes with its own set of challenges, such as initial costs and a learning curve, its advantages, including durability and cost-effectiveness for small runs, make it a favorable option in the market. As technology continues to evolve, the outlook for DTF Transfers remains promising, promising to reshape how custom designs are produced.