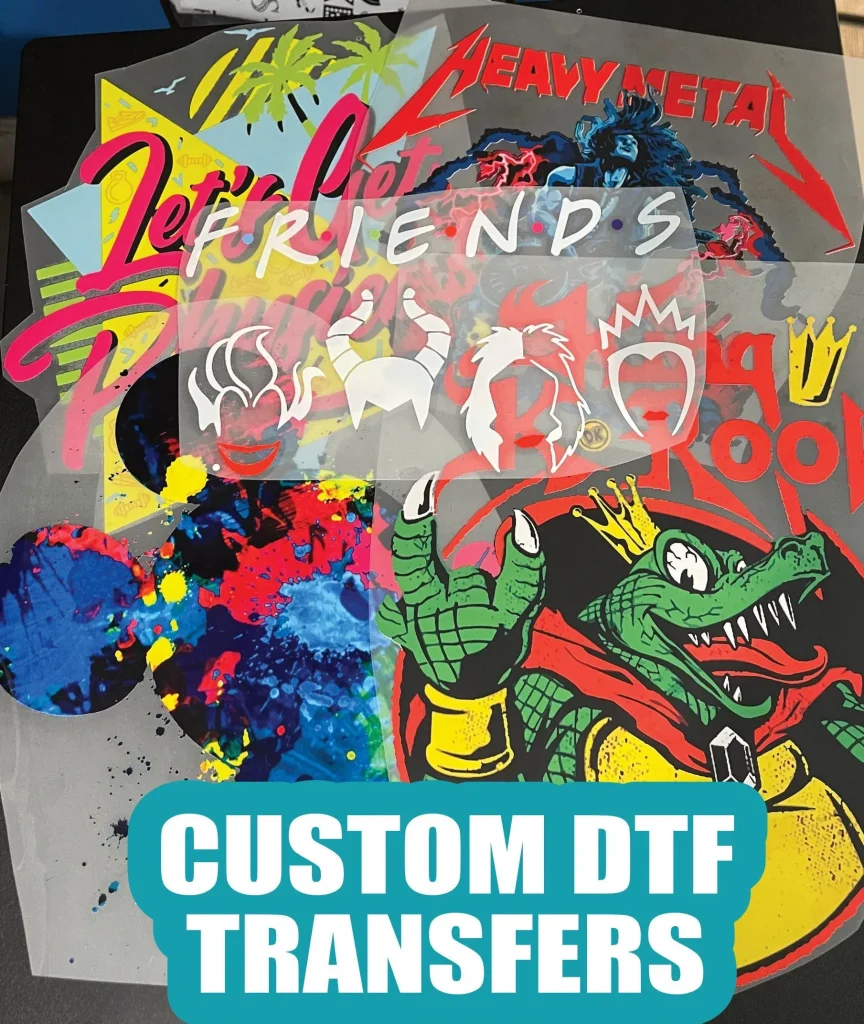

DTF transfers, or Direct-to-Film printing, represent a groundbreaking advancement in the world of custom apparel, merging vibrant aesthetics with outstanding durability. As this innovative technique gains traction, it offers businesses a streamlined method to produce flawless prints across a variety of fabrics. DTF printing techniques leverage specially formulated inks printed onto transfer films, ensuring that the finished designs maintain their vividness and quality wash after wash. With an increasing focus on printing trends and techniques that enhance user experience, the DTF process stands out for its versatility and ease of use. This article uncovers the essential tips and techniques that can help you master DTF transfers and create stunning custom apparel that resonates with your customers.

Direct-to-Film printing, often abbreviated as DTF printing, has emerged as a favorite among custom apparel producers, revolutionizing traditional printing methods. This innovative approach to fabric decoration utilizes a combination of advanced printing technologies and adhesive processes, delivering vibrant graphics with remarkable clarity and resilience. DTF transfers excel in their compatibility with diverse fabric types, making it an ideal choice for anyone looking to personalize clothing with intricate designs. As the industry shifts towards more efficient and sustainable practices, understanding the nuances of DTF printing techniques becomes increasingly vital for staying ahead in the competitive market. This guide will explore the essential elements that contribute to perfecting DTF transfers and ensuring highest quality results.

What is DTF Printing?

Direct-to-Film (DTF) printing has emerged as a revolutionary technique in the custom apparel industry, blending the attributes of both digital printing and traditional screen printing. It allows for unique designs to be printed onto a special film using DTF inks. This film, once heated and pressed onto fabric, transfers the design effortlessly, bringing vibrant colors and intricate details to life. The technique’s growing popularity can be attributed to its versatility and ease of use, making it an appealing choice for businesses looking to enhance their product offerings.

Unlike other methods such as sublimation or vinyl printing, DTF printing accommodates a vast range of fabric types, from cotton to polyester blends. This flexibility makes it ideal for custom apparel that meets diverse consumer preferences. Furthermore, the user-friendly nature of DTF printing requires minimal setup, making it accessible even for those new to the printing world. DTF’s ability to produce flawless prints without the need for weeding sets it apart in the market, positioning it as the go-to choice for high-quality garment printing.

Essential Techniques for Flawless DTF Transfers

To achieve exemplary results with DTF transfers, mastering several essential techniques is critical. The first step involves selecting high-quality transfer films, as this greatly influences the vibrancy and durability of the prints. Investing in reputable film brands ensures better adhesion and enhances the overall appearance of the designs. Neglecting the quality of materials can lead to subpar prints that may disappoint customers and affect a business’s reputation.

In addition to film quality, the choice of DTF inks plays a crucial role in the output. Using specially formulated DTF inks ensures color accuracy and longevity. With the increasing demand for eco-friendly practices, many printers are now opting for sustainable ink solutions that minimize environmental impact while delivering exceptional print quality. These practices not only resonate with environmentally-conscious consumers but also contribute to a more sustainable printing landscape.

Optimizing Printer Calibration and Settings

Proper calibration of your DTF printer is fundamental to achieving consistent results. Regular calibrations help maintain accurate color outputs and alignments, which are essential for flawless prints. When printers are not calibrated correctly, there is a higher chance of mismatched colors and alignment issues, leading to increased frustration and potential waste during production.

In combination with calibration, understanding and optimizing temperature and pressure settings is vital for enhancing transfer adhesion. Take the time to experiment with different fabrics to find the optimal settings that work best for each material type. This experimentation can significantly influence the quality of the final print, ensuring that the designs remain vibrant and intact even after multiple washes.

Mastering the Post-Processing Phase

Post-processing is a game-changer in the DTF printing process, as it directly influences the longevity and durability of the prints. After the transfer has been applied, allowing it to cure properly is crucial. Ensuring sufficient curing time prevents premature wear and fading, giving your prints a professional finish that reinforces your brand’s reputation.

Moreover, techniques such as heat sealing can further enhance the bond between the transfer and the fabric, resulting in a more resilient product. Utilizing specialized finishing sprays can also provide additional protection against fading while improving the print’s overall texture. Implementing these post-processing techniques not only maximizes the quality of your items but also enhances customer satisfaction and repeat business.

Exploring Future Trends in DTF Transfers

As the printing industry continues to evolve, DTF printing is at the forefront of emerging trends focused on sustainability and innovation. One significant development is the introduction of biodegradable inks that provide high performance without compromising environmental integrity. These inks are becoming increasingly popular among conscious consumers who prioritize eco-friendly products in their purchasing decisions.

Another exciting trend involves the use of recycled transfer films that allow brands to reduce their carbon footprints while delivering high-quality prints. The integration of digital technologies, including cloud systems for design management, also suggests a future where DTF printing could become more efficient and accessible, enabling businesses to streamline their operations while keeping pace with consumer demands.

Transitioning to DTF Printing: Tips for Success

Transitioning to DTF printing can seem daunting, but with the right approach, it can significantly enhance your offerings. Start by assessing your current equipment and determine if your printer is compatible with DTF techniques. In some cases, upgrading to a printer designed for DTF applications may provide superior results and reliability.

Additionally, invest time in training yourself or your team on the nuances of DTF printing. Knowledge about ink choices, film types, and proper techniques ensures that you maximize the quality of your transfers. Emphasizing skill development will lead to more effective use of resources, ultimately enabling you to produce higher quality custom apparel that rivals competitors in the market.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing vibrant designs onto a special film using DTF inks. This film is then applied to garments using heat and pressure, allowing for high-quality, durable prints on various fabric types.

What are the key benefits of using DTF printing techniques for custom apparel?

DTF printing techniques offer several benefits, including versatility for different fabric types, no weeding required, and the ability to produce flawless prints with vivid colors and soft finishes, making them ideal for custom apparel.

How can I achieve flawless prints with DTF transfers?

To achieve flawless prints with DTF transfers, focus on high-quality transfer films, choose the right DTF inks, calibrate your printer regularly, and experiment with temperature and pressure settings to ensure optimal adhesion.

Are DTF transfers suitable for all types of fabrics?

Yes, DTF transfers are suitable for a variety of fabrics, including cotton, polyester, and blends. However, pre-treating synthetic fabrics can enhance the bond and ensure better adhesion during the transfer process.

What are some emerging printing trends related to DTF printing?

Emerging trends in DTF printing include the use of biodegradable inks, recycled transfer films, and the integration of digital technologies, all aiming to create more sustainable and efficient printing solutions.

How do I maintain the quality of DTF prints after the transfer process?

To maintain the quality of DTF prints, it’s important to cure the print properly, apply heat sealing for extra durability, and use finishing sprays to protect against fading and improve texture.

| Key Aspect | Description |

|---|---|

| Understanding DTF Printing | DTF printing is a method that prints designs onto film, which are then transferred to fabric using heat and pressure, known for vibrant colors and durability. |

| Techniques for Flawless Prints | Key techniques include focusing on film quality, ink selection, printer calibration, temperature and pressure settings, and fabric handling. |

| Post-Processing Techniques | Essential to ensure print longevity, includes curing the print, heat sealing, and using finishing sprays. |

| Future Trends | Focus on sustainability with biodegradable inks, recycled transfer films, and advancements in digital technologies. |

Summary

DTF transfers represent a cutting-edge innovation in the printing industry, combining versatility and high-quality output for custom apparel. This method not only enhances the vibrancy of prints but also caters to a variety of fabric types, making it an ideal choice for businesses looking to thrive in a competitive market. By mastering essential techniques and staying updated with emerging trends, such as sustainable practices and technological advancements, you can significantly elevate your print quality and product offering.