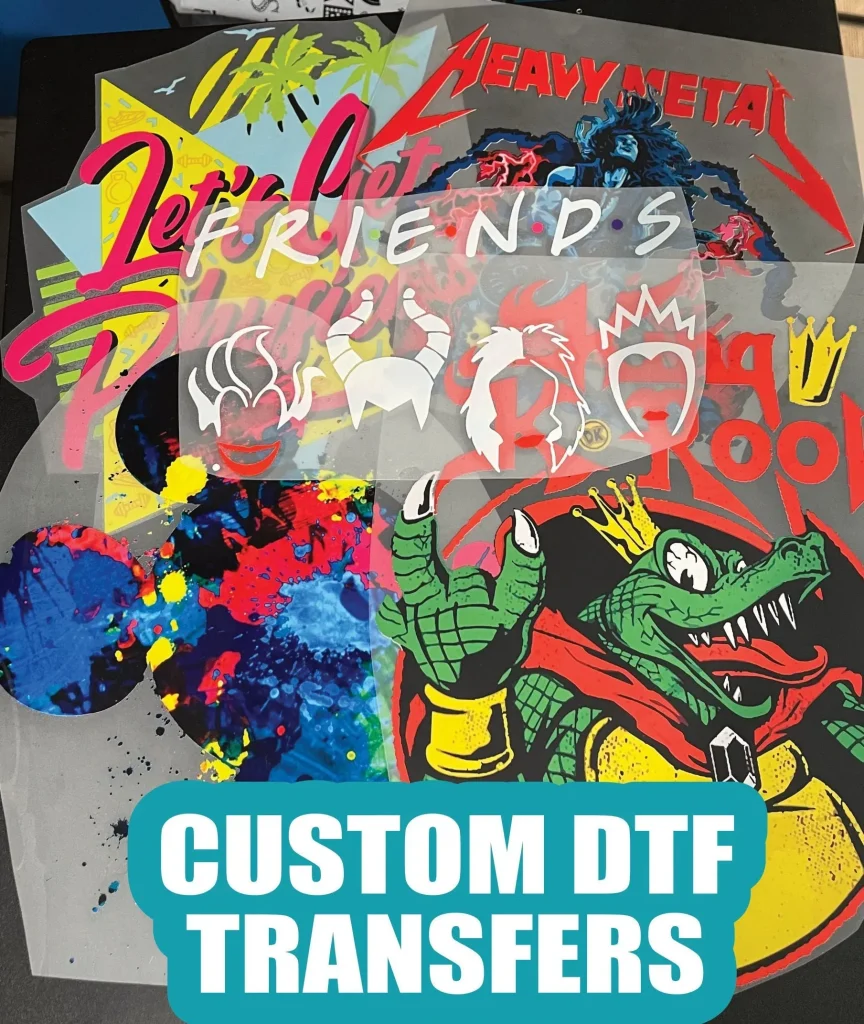

DTF transfers, or Direct-to-Film transfers, have revolutionized the way we customize apparel, making it accessible for both hobbyists and entrepreneurs alike. With DTF printing, you can create vibrant, high-quality designs that retain their integrity even after multiple washes. This innovative printing method allows users to easily produce custom apparel, enabling them to bring their unique designs to life swiftly and effectively. In this guide, we will explore how to create DTF transfers at home, covering everything from essential materials to heat press techniques that ensure flawless results. Whether you’re looking to personalize your wardrobe or start a small business, mastering DTF transfers opens up a world of creative possibilities.

Direct-to-Film transfers, commonly referred to as DTF transfers, represent a game-changing method in custom garment decoration. This technique utilizes specialized printing technology that enables high-definition graphics to be applied onto a variety of fabrics. Aspiring creators and entrepreneurs are increasingly drawn to DTF printing due to its ease of use and the stunning results it produces. In this article, we will outline a thorough approach to generating DIY DTF transfers, showcasing the required materials and the step-by-step process to ensure your designs turn out perfectly every time. From understanding the fundamentals of transfer films to applying heat press techniques, this guide will equip you with all the knowledge necessary for success.

What is DTF Printing?

DTF printing, or Direct-to-Film printing, is an innovative technique that allows you to create stunning and durable prints for custom apparel. The process involves printing designs onto a special film, which can then be transferred onto various fabrics using a heat press. Unlike traditional printing methods, DTF printing excels in producing vibrant colors and fine details, making it ideal for intricate designs and photographic images. It has gained recognition for its versatility, allowing users to print on different fabric types, including cotton, polyester, and blends.

What makes DTF printing particularly appealing is its durability. Prints created through this method are resilient against wear and tear, including repeated washing and exposure to sunlight. This ensures that your custom apparel maintains its appearance for longer periods, making it a fantastic choice for both personal use and small businesses looking to offer high-quality garments. With a growing community of DIY enthusiasts, DTF printing is set to revolutionize the custom printing industry.

Frequently Asked Questions

What are DTF transfers and how do they differ from other printing methods?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special PET film before applying them to fabric. Unlike traditional printing methods such as screen or direct-to-garment (DTG), DTF printing allows for vibrant, high-quality designs with great durability, making it ideal for custom apparel.

What materials do I need for DIY DTF transfers?

To create DIY DTF transfers, you’ll need essential materials such as a DTF printer compatible with DTF inks, transfer film, eco-solvent DTF inks, hot-melt adhesive powder, a heat press, and suitable garments, typically cotton or cotton blends for the best results.

How do I create designs for DTF transfers?

To create designs for DTF transfers, you can use graphic design software like Adobe Illustrator or CorelDRAW. Ensure to create your design at the desired resolution and mirror it before printing, as the image will flip during application.

What is the step-by-step process of applying DTF transfers on fabric?

The step-by-step process of applying DTF transfers involves: 1) creating and mirroring your design, 2) printing on transfer film using a DTF printer, 3) applying adhesive powder on the wet ink, 4) curing the adhesive with heat, 5) pressing the film onto the garment, and 6) peeling off the film once cooled to reveal the design.

What are some best practices for successful DTF printing?

For successful DTF printing, ensure your DTF printer is well-calibrated, preheat your garment before applying the transfer, and choose fabric types wisely. Regular maintenance of your printer and heat press will also enhance the quality of your transfers.

Where can I find tutorials on how to create DTF transfers?

You can find helpful tutorials on how to create DTF transfers on platforms like YouTube, where various creators provide step-by-step visual guides tailored for beginners and enthusiasts looking to improve their DTF printing skills.

| Step/Material | Description |

|---|---|

| Understanding DTF Transfers | DTF printing involves printing designs onto a special film before applying them to fabric, ensuring vibrant, long-lasting graphics. |

Summary

DTF transfers are revolutionizing the way custom apparel is created, allowing individuals to design vibrant, long-lasting graphics with relative ease from home. The process of creating these transfers involves specific materials such as a DTF printer, special transfer film, and eco-solvent inks, all essential for achieving high-quality results. Following a methodical step-by-step guide, from design creation to application, ensures that your transfers adhere flawlessly to fabrics. The popularity of DTF printing continues to rise among hobbyists and small businesses alike, with an ever-growing availability of resources and community support. By mastering the art of DTF transfers, creators can not only express their individuality but also tap into a rewarding business opportunity.