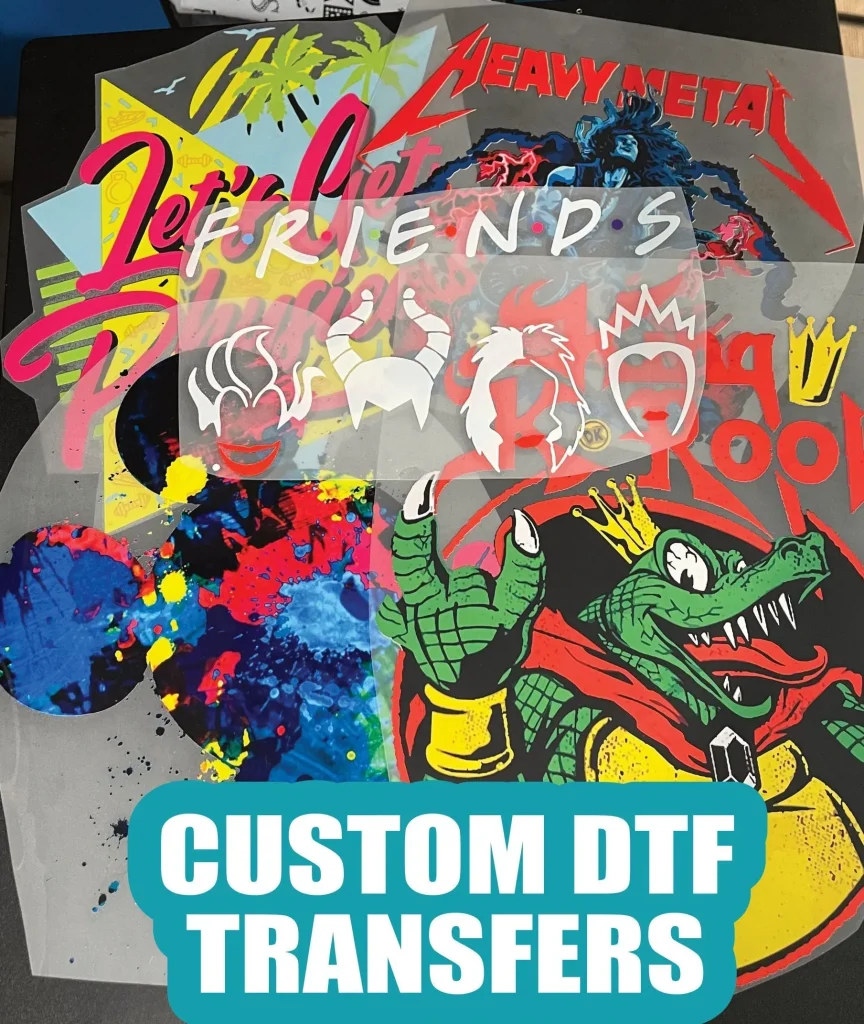

DTF transfers, or Direct to Film transfers, are a groundbreaking innovation in the world of textile printing, making it easier than ever to achieve striking, high-quality designs on various fabrics. This technique allows creators to bring their custom DTF designs to life with beautiful colors and fine details that captivate viewers. Whether you’re a hobbyist looking to personalize apparel or a professional aiming to enhance production capabilities, understanding how to use a DTF printer is essential for maximizing creativity. Through the DTF printing process, you’ll discover how quickly you can produce vibrant results that outperform traditional methods. In this guide, we’ll delve into creating DTF transfers and the materials needed for exceptional results.

Direct to Film application is rapidly gaining traction among designers and fabric printers for its remarkable adaptability and ease of use. This technique is perfect for anyone interested in textile decoration, allowing for the seamless application of intricate designs to a variety of materials. Mastering the art of DTF prints involves not just selecting the right ink but also utilizing high-quality film for outstanding outcomes. As this printing method expands in popularity, exploring alternatives such as heat transfer or screen printing can provide additional insights into the world of fabric embellishment. In the following sections, we will guide you through the preparation, printing, and application processes to create eye-catching textile designs.

Getting Started with DTF Printing Materials

Before embarking on your DTF transfer journey, it’s essential to gather the right materials. DTF printing requires a specific set of tools and resources to ensure high-quality results. First, you’ll need a reliable DTF printer, which generally utilizes CMYK inks, alongside white ink to enhance vibrancy. Furthermore, DTF transfer films must be acquired, which are specially designed to handle the ink and facilitate proper adhesion during the heat transfer process.

In addition to the printer and transfer film, you’ll also need adhesive powder, which acts as a bonding agent between the ink and the fabric. A heat press is crucial for applying appropriate heat during the transfer, ensuring durability and a smooth finish. Lastly, having graphic design software, such as Adobe Illustrator, on hand will allow you to create stunning and custom DTF designs that can be brought to life on fabric.

Understanding the DTF Printing Process

The DTF printing process is unique compared to other printing methods. It starts with designing your artwork in graphic design software, paying attention to dimensions and resolution for clarity and detail. After that, the artwork is printed onto specialized DTF transfer film, which enables the ink to adhere correctly. This initial printing must be followed by a careful application of adhesive powder, ensuring it sticks while the ink is still wet.

Once the adhesive powder is applied, the heat press plays a vital role. The film is subjected to heat which activates the adhesive, permanently bonding the ink to the film in preparation for the final transfer to fabric. This combination of heat and pressure is what gives DTF transfers their durability and vibrant finish, making it an excellent choice for a wide array of fabric applications.

Steps to Create Custom DTF Designs

Creating custom DTF designs begins with a strong concept, which you can design using graphic software that supports high-resolution outputs. Your final design should be prepared with the right technical specifications, ensuring it fits well within the dimensions of the garment. Additionally, you must remember to mirror the image before printing to ensure that it appears correctly on fabric, a crucial step in the DTF process that can’t be overlooked.

After the design is mirrored, print it using your DTF printer set to optimal settings for the best color accuracy. This ensures that your artwork translates beautifully from digital canvas to physical fabric. Experimenting with different artwork styles and color combinations can lead to impressive custom DTF designs, perfect for showcasing creativity in various applications, from personal projects to merchandise.

Tips for Successful DTF Transfer Application

To achieve the best results when applying DTF transfers, following specific best practices is key. First, ensuring your fabrics are clean and lint-free can drastically improve the effectiveness of the transfer. Pre-pressing the fabric for a few seconds before applying the transfer can also remove moisture and wrinkles, providing a smooth surface for the design. This simple preparation can help achieve a more professional look and longevity.

During the heat application, precision is crucial. Make sure the temperature is set correctly to around 320°F (160°C) and that the heat press is evenly applied for approximately 10-15 seconds. This timing ensures the adhesive bonds properly without scorching the fabric. Lastly, always allow the fabric to cool slightly before peeling away the film to prevent any potential tearing of the design.

Caring for DTF Transfers

Maintaining the quality of your DTF transfers is essential for ensuring they last through multiple washes. To extend their lifespan, it’s advisable to wash transferred fabrics in cold water rather than hot, which can cause fading or peeling. Avoiding bleach and harsh detergents will also help keep your designs looking fresh and vibrant.

When it comes to drying DTF transferred items, hang them to dry instead of placing them in a tumble dryer. The heat and tumbling action of a dryer can weaken the adhesive over time, potentially damaging the transfer. By following these care instructions, you’ll keep your DTF transfers looking as brilliant as the day they were first applied.

Versatile Applications of DTF Transfers

DTF transfers provide significant versatility across various applications, making them an ideal choice for hobbyists and professionals alike. These transfers can be applied to a variety of fabrics, including cotton, polyester, and even blends, enabling you to create unique designs for apparel ranging from t-shirts to hoodies and caps. This flexibility allows for personalized clothing lines or even custom gifts for friends and family.

Not only are DTF transfers perfect for apparel, but they are also suitable for a range of accessories. Have fun creating customized tote bags, pouches, and even home décor items like cushions. DTF transfers can be an excellent way to market promotional materials, such as branded merchandise for events, ensuring your designs stand out and make a memorable impression.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process involves printing a design onto special transfer film using a DTF printer, which applies CMYK inks plus white ink for enhanced vibrancy. The printed film is then dusted with adhesive powder while the ink is wet, allowing for proper bonding. After applying heat with a heat press at approximately 320°F, the design can be transferred onto fabrics, resulting in vivid and durable prints.

How do I create custom DTF designs for my projects?

To create custom DTF designs, start by using graphic design software like Adobe Illustrator. Design your artwork to the correct dimensions and resolution, and remember to mirror your image before printing. Once your design is ready, use a DTF printer to print it onto transfer film, ensuring the right printer settings for optimal results.

What materials do I need for DTF transfers?

To create DTF transfers, you will need several materials: a DTF printer (for printing on film), special transfer film for ink adhesion, adhesive powder for bonding, a heat press to apply heat during the transfer process, tweezers or heat-resistant gloves for safety, and graphic design software for creating your designs.

How do I use a DTF printer effectively?

To use a DTF printer effectively, ensure you have the correct settings for DTF printing. Load the printer with the special transfer film and print your mirrored design. It’s important to periodically maintain your printer, check ink levels, and clean the print heads to prevent quality issues.

What are the care instructions for DTF transfers after application?

To maintain DTF transfers, wash items in cold water to avoid fading and hang to dry instead of using a dryer. This careful handling will help preserve the vibrancy and durability of the transfer, ensuring it lasts through multiple washes while keeping the design intact.

What types of fabrics can I use DTF transfers on?

DTF transfers are versatile and can be used on a variety of fabrics, including cotton, polyester, and fabric blends. This allows for creative applications on apparel, accessories such as tote bags, and promotional items, making DTF a popular choice for various projects.

| Step | Description |

|---|---|

| 1: Design Creation | Create your artwork in graphic design software and remember to mirror it before printing. |

| 2: Print the Design | Load the DTF printer with transfer film and print the mirrored design. |

| 3: Apply Adhesive Powder | Sprinkle adhesive powder on the wet ink for proper bonding. |

| 4: Heat Application | Use a heat press at 320°F for 10-15 seconds to lock in the adhesive. |

| 5: Peel and Transfer | Cool the film slightly, peel off the backing, and place on fabric. |

| 6: Final Peeling | After the second heat press, peel away the film to reveal the design. |

Summary

DTF transfers have revolutionized fabric printing, offering vibrant and intricate designs that are durable and versatile. By mastering the step-by-step process detailed in this guide, anyone can create stunning DTF transfers that stand out in clothing, accessories, and promotional materials. This technology not only enhances the visual appeal of fabric prints but also ensures long-lasting results, making it increasingly popular among both hobbyists and professionals. Dive into the world of DTF transfers and experiment with various designs to elevate your textile projects today!