DTF Transfers, a revolutionary method in the world of printing, are transforming how garments are decorated. Utilizing cutting-edge Direct-to-Film technology, this innovative approach enables the transfer of vibrant and durable designs onto fabrics with unmatched quality. With an impressive ability to print on various materials, including both light and dark fabrics, DTF printing not only simplifies the process but also reduces costs for businesses and creators alike. The benefits of DTF are clear: less waste, lower setup costs, and outstanding print quality make it a preferred choice in custom apparel production. In this comprehensive DTF Transfers guide, we explore how this technique is shaping the future of textile printing for artists and businesses across the industry.

Exploring the realm of DTF transfers opens up a discussion about its associated concepts, such as Direct-to-Film technology and DTF printing. This printing technique, often referred to as film transfers, is gaining popularity due to its ability to produce high-quality images that adhere seamlessly to a variety of fabric types. The versatility of film-based printing means it’s not restricted only to textiles; it can also be applied to a diverse array of materials, presenting opportunities for custom designs in many industries. As we delve into the advantages of this printing method, we will highlight how its efficient process and community-building initiatives further enhance its appeal among enthusiasts and professional printers alike.

Understanding the DTF Printing Process

DTF (Direct-to-Film) printing is revolutionizing the way designs are transferred onto fabrics. The process begins by printing a digital artwork onto a specially coated PET film. This method ensures that every detail of the design is captured with exceptional clarity and vibrancy. By using specialized inks, the printed film can produce striking colors that remain intact even after multiple washes. This initial printing step is crucial, as it sets the foundation for the high-quality transfer that DTF technology is known for.

The next key stage involves applying a heat-activated adhesive to the printed design on the film. This step is essential as it prepares the image for the final transfer onto fabric. By passing the film through a heat tunnel, the adhesive melts, creating a bond that allows for a clean and precise application on various substrates. This two-step process highlights the efficiency of DTF technology, making it an attractive option for both DIY enthusiasts and professional printers.

The Versatile Applications of DTF Transfers

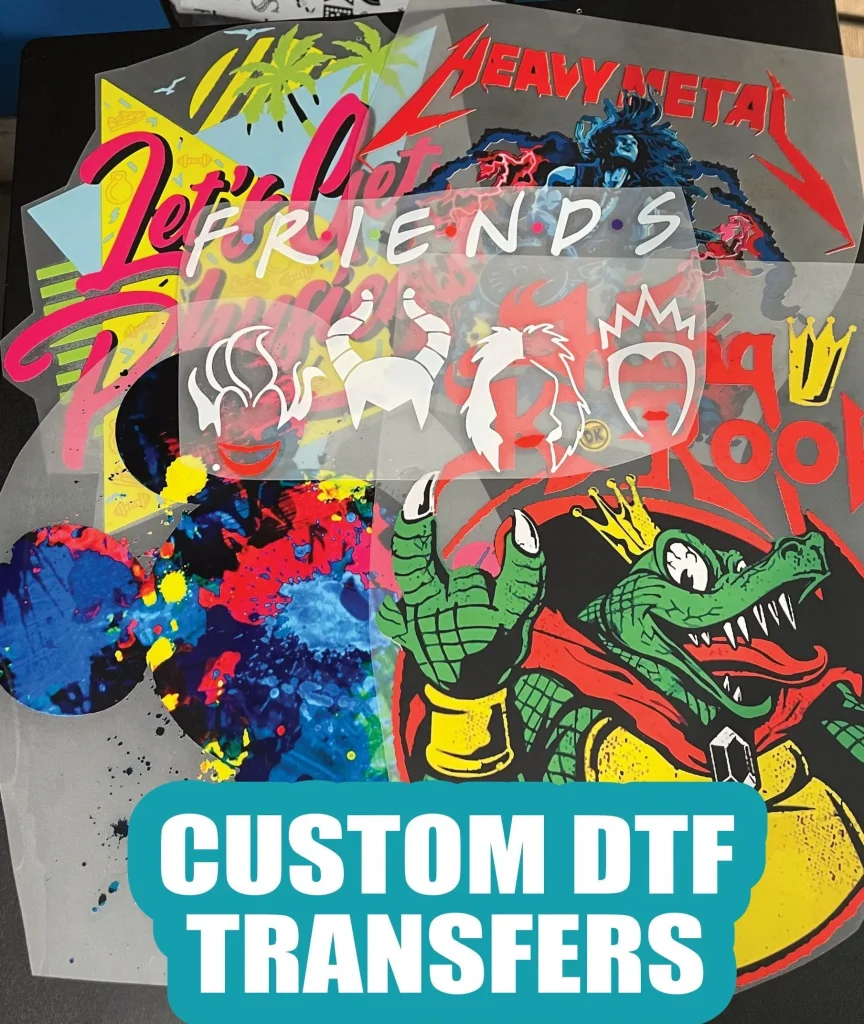

One of the standout features of DTF transfers is their ability to print on a wide variety of materials and fabric types. This versatility allows businesses to expand their product offerings, catering to diverse customer needs. From cotton t-shirts to polyester jackets and even leather accessories, DTF printing adapts seamlessly to different substrates. As a result, designers can experiment with a multitude of styles, textures, and colors, making it possible to create unique items that stand out in a crowded market.

Moreover, DTF transfers excel in producing designs with intricate details and vibrant colors. Unlike traditional methods such as screen printing, which can struggle with complex designs, DTF technology ensures that every element is rendered with stunning accuracy. This capability makes DTF an ideal choice for fashion brands and custom apparel businesses seeking to offer eye-catching products without compromising on the quality or richness of the designs.

The Cost-Effective Nature of DTF Technology

DTF printing offers significant cost advantages, especially for small businesses or startups venturing into the custom apparel industry. Compared to traditional screen printing, the setup costs associated with DTF technology are markedly lower. With no requirement for extensive color separations or large batches, businesses can print smaller quantities economically. This flexibility enables entrepreneurs to test new designs or cater to limited edition products without incurring heavy financial burdens.

Additionally, DTF printing is known for its efficient use of materials, resulting in reduced waste. The digital nature of the process means that ink usage is optimized, which not only saves costs but also makes DTF a more eco-friendly printing option. The reduction in excess inventory and materials not only helps the environment but also supports a sustainable business model that appeals to increasingly eco-conscious consumers.

Recent Innovations in DTF Printing

As DTF printing continues to gain popularity, the market has witnessed substantial innovations aimed at enhancing the printing experience. Large-format printers have emerged, allowing for more extensive designs and increasing production capabilities. These advancements cater to high-demand projects and enable businesses to upscale their operations efficiently. By investing in larger machines, companies can capitalize on the growing interest in DTF printing, positioning themselves as leaders in the market.

In addition to equipment advancements, web-to-print platforms have been developed to streamline the custom design and ordering process. These advancements simplify the user experience, allowing customers to upload their designs easily and select options that cater to their specifications. Such platforms not only enhance accessibility to DTF products but also foster a more interactive and engaging relationship between businesses and their customers.

Engaging with the DTF Community

The DTF printing community is vibrant and evolving, with a wealth of knowledge being shared through workshops, webinars, and online forums. Events like ‘Discovering DTF’ aim to bring together industry professionals to exchange insights, troubleshoot challenges, and discuss the latest trends. Participation in such initiatives not only enriches individual understanding but also fosters networking opportunities that can lead to collaboration and growth within the DTF space.

Furthermore, educational initiatives targeting both novices and experienced printers serve to demystify the DTF process. With access to comprehensive guides and expert advice, newcomers can confidently explore this printing technology, while veterans can refine their skills and keep up with industry advancements. This focus on education underscores the importance of community engagement in propelling the DTF sector forward.

DTF Printing Compared to Traditional Methods

When evaluating DTF technology against other printing methods like screen printing and sublimation, its unique advantages become clear. DTF printing combines the best aspects of both traditional and digital printing techniques, offering ease of use alongside high print quality. Users often report a more straightforward workflow with DTF, from design to production, making it an appealing option for businesses looking to streamline their operations.

Moreover, the print quality provided by DTF printing is exceptional, matching, and often surpassing that of traditional screen printing with its rich colors and fine detail. This allows brands to maintain a competitive edge in the market, offering products that not only look good but also stand the test of time, appealing to customers looking for durability in their apparel.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film Transfers, involve a two-step process where a design is printed onto a special PET film before being transferred onto fabric. This process includes printing the design with high-quality inks and applying an adhesive powder to effectively bond the print to various materials, ensuring vibrant and durable results.

What are the benefits of DTF Printing compared to traditional methods?

DTF Printing offers several benefits over traditional methods like screen printing, including lower setup costs, the ability to print on both light and dark fabrics without pretreatment, and reduced material waste, making it an eco-friendlier option for small businesses looking for cost-efficient solutions.

Can DTF Transfers be applied to any fabric type?

Yes, DTF Transfers are versatile and can be applied to a variety of fabric types including cotton, polyester, and even leather. This adaptability allows for complex designs and colors, making it suitable for a wide range of apparel and merchandise.

Is DTF technology a cost-effective solution for small businesses?

Absolutely! DTF technology is known for its cost-effectiveness, as it reduces setup costs significantly compared to traditional screen printing. This allows small businesses to produce high-quality prints in smaller quantities without incurring heavy expenses.

What recent developments have emerged in DTF Printing technology?

Recent developments in DTF Printing have included the introduction of large-format printers for greater design capabilities and the launch of web-to-print platforms such as Snuggle, which streamline the custom design and ordering process, enhancing the accessibility of DTF products.

How does DTF Printing compare to sublimation in terms of print quality?

DTF Printing provides exceptional print quality that rivals sublimation, offering vibrant colors and high detail retention. It combines the ease of digital printing with the quality found in traditional methods, resulting in superior outcomes for various textile applications.

| Key Point | Description |

|---|---|

| What Are DTF Transfers? | A method of textile printing that utilizes Direct-to-Film technology, producing high-quality designs. |

| Process Overview | Involves printing on PET film followed by adhesive application to ensure vibrant, durable designs. |

| Versatility of DTF Technology | Can print on light and dark fabrics as well as various material types including cotton and leather. |

| Cost-Efficiency | Lower setup costs and reduced waste make it an eco-friendly and economical option for businesses. |

| Recent Developments | Innovations include large-format printers and web-to-print platforms, enhancing accessibility and production. |

| Community Engagement | Educational initiatives and webinars foster knowledge-sharing in the DTF printing community. |

| Comparison with Other Methods | DTF provides ease of use and high print quality, competing effectively with sublimation and screen printing. |

Summary

DTF Transfers are revolutionizing the garment printing industry by providing a seamless way to produce stunning, high-quality textile prints. The comprehensive advantages of this Direct-to-Film technology not only facilitate vibrant and long-lasting designs but also offer cost-efficiency and versatility across various fabric types. As more businesses and creatives adopt DTF transfers, they unlock the potential for intricate designs without the burden of high setup costs traditionally associated with printing methods. The ongoing innovations in DTF technology promise to enhance product offerings and accessibility, making it a pivotal option in the world of custom apparel production.