DTF Supplies are at the forefront of revolutionizing the printing industry, particularly in the realm of Direct-to-Film (DTF) printing. This innovative method allows for vibrant, high-quality prints that capture intricate designs with ease. To succeed in this growing market, it is essential to equip yourself with the best DTF films, DTF inks, and a reliable DTF heat press that ensures precise application. Additionally, understanding the importance of DTF adhesive powder will take your print quality to the next level, enabling designs to adhere perfectly to fabric. As we explore the top supplies for embarking on a successful DTF printing venture, it’s clear that the right tools are vital for achieving remarkable results.

In the exciting world of garment decoration, supplies for Direct-to-Film printing play a crucial role in enabling businesses to create stunning designs with ease. Known for their versatility, these materials include high-quality transfer films and specialized printing inks that facilitate vibrant color reproduction. Equipping your workspace with a dependable heat press machine and essential adhesive products can dramatically enhance the finish of your printed apparel. By harnessing the power of innovative printing technology, businesses can cater to the growing demand for customized items while ensuring longevity and quality in each print. As we dive deeper into the essentials for thriving in the DTF printing landscape, we’ll uncover the best strategies and tools available to help you stand out in this competitive market.

The Rise of DTF Printing Technology

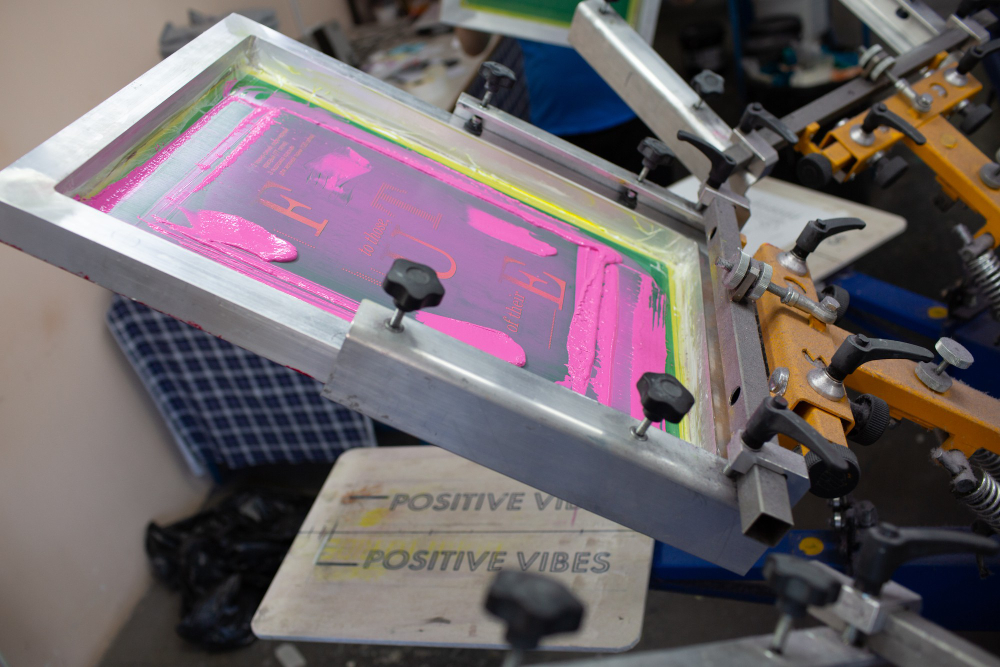

DTF printing technology has revolutionized garment decoration by merging the best features of traditional and digital printing methods. This reliable technique allows for full-color images to be printed with stunning detail on a special film and transferred onto fabrics with heat and pressure. With its ease of use and versatility, DTF has rapidly gained popularity among printing businesses, leading to a surge in demand for high-quality DTF printing equipment. Companies are quickly adapting by investing in advanced machines to stay competitive in this dynamic market.

As the adoption of DTF printing grows, many businesses are discovering that the technology opens doors to new creative possibilities. Whether it’s vibrant promotional apparel or intricate designs for custom merchandise, the applications are endless. DTF’s ability to print on a variety of fabrics without the need for complex setups reduces production time and enhances workflow efficiency, making it an efficient choice for commercial printing.

Key DTF Supplies for Optimal Printing

When exploring the landscape of DTF printing, understanding the key supplies involved is essential for successful output. Among these, high-quality DTF inks play a pivotal role; they are the foundation of every vibrant piece produced. Brands like Epson and Mimaki provide inks that are formulated specifically for DTF applications, ensuring superior color accuracy and longevity. Without the right inks, achieving that striking finish that customers expect can be impossible.

In addition to the inks, the selection of the right transfer films cannot be overstated. The choice of transfer film directly impacts the adhesion and durability of the print on various fabrics. High-performance films from noted brands such as Siser and Palladio enhance the bond between the ink and fabric, leading to prints that withstand washing and wear. Therefore, investing in top-tier DTF supplies is non-negotiable for businesses aiming to deliver high-quality results.

Choosing the Best DTF Films for Your Needs

The best DTF films are specifically designed to meet the rigorous demands of printing professionals. Selecting the right film ensures that the images printed are vibrant and maintain their clarity after washing. Notably, there are several options available, with choices catering to different fabric types and printing conditions. High-quality films should allow for easy peeling and should be compatible with various DTF inks to provide optimal results.

Furthermore, professional printers often recommend testing multiple films to find which performs best with specific ink and adhesive combinations. The film’s compatibility with the heat press machine is also essential; models like TUSY and Fancierstudio provide reliable results across different film brands. By systematically evaluating various DTF films, printers can establish a consistent quality that meets client expectations and enhances their business reputation.

Understanding DTF Heat Press Machines

A reliable DTF heat press machine is fundamental to the success of the printing process, as it directly influences the quality of the end product. It’s essential that the machine can maintain consistent temperature and pressure settings—variabilities in these factors can lead to poor adhesion or ruined prints. Popular models available in the market, recognized for their durability and precision, can be the key to achieving professional-grade results.

Additionally, understanding the various features of heat press machines can help in selecting the most suitable one for a particular business setup. For example, some machines come with digital controllers for easy monitoring and adjustments, which can significantly streamline the printing process. Evaluating machines based on user reviews and expert recommendations can further assist in making a sound investment for your DTF printing endeavors.

Utilizing DTF Adhesive Powder Effectively

DTF adhesive powder plays a crucial role in the printing process, serving as a bonding agent that holds the ink securely to the fabric during application. It’s important for businesses to choose a high-quality adhesive powder, such as those from Firebird or Avery Dennison, which can create strong, enduring bonds. Proper application of adhesive powder not only increases the longevity of prints but also enhances the overall finish of the garment.

Printer operators must master the technique of applying adhesive powder uniformly, as uneven application can lead to inconsistencies in print quality. Furthermore, experimenting with different quantities and application methods can yield improved results tailored to specific projects. Investing time and resource into understanding how to effectively use DTF adhesive powder will maximize the performance of the DTF printing setup, ultimately leading to satisfied customers.

Best Practices for DTF Printing Success

To thrive in the DTF printing industry, adhering to best practices is essential. Regularly calibrating printers and heat press machines is key to achieving the desired print quality. Calibration ensures that equipment operates at peak efficiency—this means thicker fabrics may require different settings than thinner ones, so adjustments must accommodate these variations to maintain excellence across various materials.

Moreover, routine maintenance of equipment cannot be overlooked. Printers need regular cleaning to prevent clogs and ensure smooth ink flow, while heat presses should be checked for temperature accuracy. By implementing a diligent maintenance schedule, businesses can extend the lifespan of their equipment, ensure quality prints, and reduce costly downtime, ultimately leading to increased productivity and profitability.

Frequently Asked Questions

What are the best DTF inks for vibrant prints?

To achieve vibrant and high-quality prints in DTF printing, it is essential to use the right DTF inks. Brands like Epson and Mimaki are widely recognized for their reliable DTF inks that deliver excellent color accuracy and consistency. Opting for quality inks allows you to enhance the vibrancy of your designs across a variety of fabrics.

How do I choose the best DTF films for printing?

Choosing the right DTF films is critical for successful transfers. Look for films from reputable brands like Siser and Palladio which offer excellent coatings for ink adhesion. These high-quality DTF films help maintain clarity and vibrancy of your prints on different fabric types, ensuring long-lasting results.

What type of heat press is recommended for DTF printing?

A reliable heat press machine is vital for DTF printing. It should provide precise temperature and pressure for optimal results. Popular models such as TUSY and Fancierstudio are favored for their robust performance. Investing in a quality heat press machine ensures that your DTF transfers achieve the best possible outcome.

Why is adhesive powder important in DTF printing?

Adhesive powder acts as a bonding agent in DTF printing, ensuring that the printed design adheres effectively to the fabric after heat application. Using high-quality options like Firebird or Avery Dennison guarantees a strong and durable bond, which is essential for creating lasting, high-quality prints.

What role do pre-treatment solutions play in DTF printing?

Pre-treatment solutions enhance ink adherence and color vibrancy in DTF printing, especially on polyester fabrics. By applying a pre-treatment solution, the prints not only stand out but also last longer. This step is crucial for optimizing the quality of prints on various materials used in garment printing.

How can I maintain my DTF printing equipment for optimal performance?

To ensure optimal performance in DTF printing, regularly maintain and clean your equipment. This includes calibrating your printer and heat press to uphold consistent results, and cleaning printer heads to prevent issues. Routine maintenance helps extend the lifespan of your DTF supplies and enhances overall print quality.

| Key Supply | Description | Recommended Brands |

|---|---|---|

| DTF Inks | Essential for vibrant colors and details. | Epson, Mimaki |

| Transfer Films | Vital for adhering ink to fabric. | Siser, Palladio |

| Adhesive Powder | Binds the ink to fabric post-heat application. | Firebird, Avery Dennison |

| Heat Press Machine | Delivers necessary temperature and pressure for quality. | TUSY, Fancierstudio |

| Pre-Treatment Solutions | Enhances adherence and vibrancy for some fabrics. | Various brands |

Summary

DTF Supplies are integral to achieving success in the garment printing industry through Direct-to-Film printing. With the right combination of high-quality DTF inks, transfer films, adhesive powders, heat press machines, and pre-treatment solutions, businesses can create stunning, durable prints that meet customer expectations. The current trends in sustainability, technology, and customization further emphasize the need for businesses to adapt and innovate. By continuing to invest in quality supplies and staying informed about industry advancements, anyone can excel in the dynamic world of DTF printing.