DTF Supplies are revolutionizing the landscape of professional printing, particularly in the apparel and textile industries. As Direct to Film (DTF) printing technology gains traction, the demand for high-quality DTF printing equipment is on the rise. These essential tools, including transfer films, adhesive powder for DTF, and reliable heat presses, are crucial for creating eye-catching, durable prints that satisfy the modern market’s needs. With DTF Supplies, businesses can achieve vibrant, long-lasting designs on a variety of fabrics, ensuring their creations stand out in a competitive environment. This introduction to DTF printing and the supplies necessary to maximize its potential sets the foundation for exploring the intricate details of this innovative printing method.

When discussing the essentials of DTF printing, one can refer to it as a method of transferring vivid images onto textiles using film-based techniques. This approach, often termed “film transfer printing,” leverages specialized printing equipment designed for high-quality outputs. The process involves using a unique film, often paired with specific adhesive powders and heat application tools, to achieve results that are both bold and lasting. By investing in professional-grade printing gear, innovators and entrepreneurs in the custom apparel sector can tap into the myriad possibilities that this technology offers. The successful adoption of film transfer processes is paving the way for fresh designs and customization options in the textile industry.

Understanding DTF Printing Technology

Direct to Film (DTF) printing technology represents a remarkable shift in the printing landscape, particularly within the textile industry. Unlike traditional methods such as Direct to Garment (DTG) printing, which requires a direct application of ink onto fabric, DTF printing uses a sophisticated process involving transfer films. These films act as a medium, allowing intricate designs to be printed onto a PET film before being transferred to various fabric types. This versatility affords businesses the opportunity to produce stunning, high-quality prints on fabrics ranging from cotton to synthetics, ensuring vibrant results that stand the test of time.

The beauty of DTF printing lies in its efficiency and adaptability. The process eliminates the limitations often faced with fabric compatibility in other printing methods. Designed for intricate designs, this technology caters to custom apparel businesses and entrepreneurs aiming to deliver high-quality, detailed prints. As the demand for personalized and custom products grows, understanding DTF technology becomes crucial for anyone looking to make their mark in the printing sector.

Essential DTF Supplies for Quality Prints

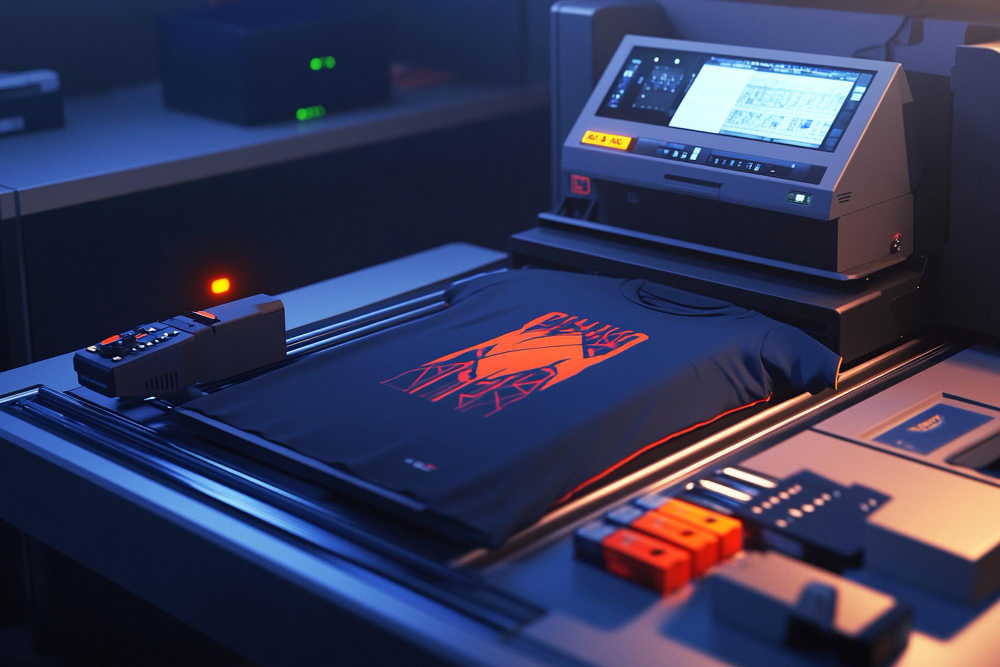

To succeed in DTF printing, investing in essential supplies is non-negotiable. Among these are specialized DTF printers, which utilize water-based inks tailored for transfer films. The right printer not only guarantees high-quality output but also enhances the overall efficiency of the printing process. Additionally, selecting high-grade transfer films is crucial since they are designed specifically for DTF applications, ensuring that the vibrant inks adhere perfectly and stand out on the fabric.

Moreover, quality adhesive powder plays a pivotal role in achieving lasting results. After the design is printed on the transfer film, a layer of adhesive powder is applied, which, when melted through heat, creates a strong bond between the fabric and the print. In addition, having a reliable heat press is integral to the application process, as it evenly distributes heat and pressure, ensuring that the transfer is executed flawlessly every time. Collectively, these supplies form the backbone of a successful DTF printing operation.

Frequently Asked Questions

What are the essential DTF supplies needed for high-quality printing?

To achieve professional-quality results in DTF printing, you need several essential supplies: a specialized DTF printer, transfer film designed for DTF applications, adhesive powder for DTF, a reliable heat press for DTF printing, and high-quality inks compatible with both your printer and fabrics.

How does transfer film affect DTF printing outcomes?

Transfer film is crucial in DTF printing as it serves as the medium for your designs. The quality of the transfer film directly influences the vibrancy and clarity of the final prints. Using high-grade PET transfer film ensures better adhesion and color reproduction after heat transfer.

Why is adhesive powder important in DTF printing?

Adhesive powder for DTF is vital because it ensures that the printed ink adheres permanently to the fabric. After printing your design on the transfer film, applying adhesive powder locks the ink in place during the heat transfer process, creating a durable bond between the print and the fabric.

What should I look for in a heat press for DTF printing?

When selecting a heat press for DTF printing, look for even heat distribution and adjustable pressure settings. A high-quality heat press will ensure that the transfer film adheres properly to the fabric, producing consistent and professional-grade prints.

Are there any trends impacting the DTF supplies market?

Current trends in the DTF supplies market include enhanced color vibrancy due to innovative inks, the rise of eco-friendly options such as recyclable transfer films, and an overall market expansion driven by increased interest in customized apparel.

What challenges do newcomers face when investing in DTF printing equipment?

Newcomers to DTF printing often face challenges like the initial investment costs for DTF printers, transfer films, and heat presses. Additionally, integrating these technologies into existing workflows can be complex, requiring careful planning and strategy to maximize efficiency.

| Key Elements | Description |

|---|---|

| DTF Printer | Specialized printers utilizing water-based inks for transfer films. |

| Transfer Film | PET film designed to transfer vibrant designs onto fabric. |

| Adhesive Powder | Ensures ink adheres to fabric during the heat transfer process. |

| Heat Press | Applies heat and pressure to create a strong bond between film and fabric. |

| Inks | High-quality inks that enhance durability and color retention. |

Summary

DTF Supplies are essential for anyone looking to achieve professional-quality prints in today’s dynamic printing market. Utilizing the right gear—like specialized DTF printers, transfer films, and high-quality inks—ensures optimal results that stand out in vibrant color and clarity. Now, more than ever, custom printing businesses are embracing this cutting-edge technology, driven by trends such as improved color vividness and sustainability. However, it is crucial to tackle initial investment costs and workflow integration to fully leverage the potential of DTF. By adhering to best practices, companies can enhance output consistency and quality. Investing in DTF Supplies not only elevates print quality but also positions businesses for unprecedented growth in a competitive field.