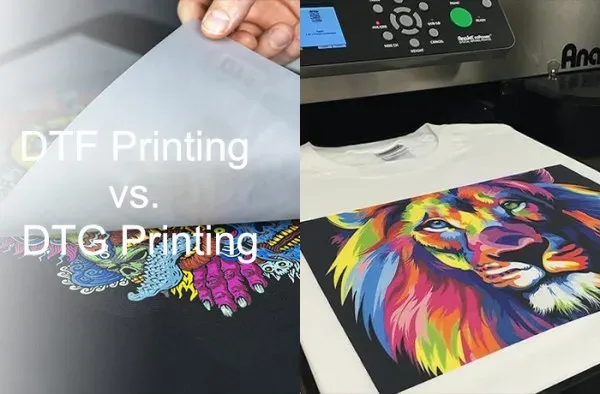

When it comes to custom printing solutions, DTF printing vs. DTG is a significant topic of discussion within the printing technology landscape. Understanding the nuances of these two methodologies—Direct-to-Film (DTF) and Direct-to-Garment (DTG)—can help businesses select the most effective method for their needs. Each printing technology possesses distinct advantages, catering to different types of projects and customer preferences. With the ability to deliver vibrant colors and high-quality designs, these printing approaches are vital for modern business printing solutions. In this article, we will delve into the essential aspects of DTF printing vs. DTG, equipping you with the necessary insights to navigate your options effectively.

In the realm of garment printing, business owners often debate between various techniques, with two standout options being film transfer printing and fabric inkjet printing. These innovative methods provide distinct advantages that can cater to a wide array of production needs and artistic visions. While film transfer printing offers bold colors and adaptability across fabrics, fabric inkjet printing shines with exceptional image quality and customization potential. By exploring the strengths and applications of these technologies, businesses can discover the optimal solution to elevate their custom printing endeavors and meet diverse client demands.

Understanding DTF Printing Process and Benefits

Direct-to-Film (DTF) printing is revolutionizing the custom printing landscape by merging efficiency with high-quality output. The process begins when vibrant designs are printed onto a specialized film. After that, a heat transfer process allows these designs to adhere seamlessly to various fabric types. This technology is particularly advantageous for businesses looking for flexibility across different materials, enabling them to cater to a wider range of customer preferences. In addition, DTF boasts the ability to deliver intricate designs without losing detail, an essential factor in enhancing a brand’s visual appeal.

Moreover, the cost-effectiveness of DTF printing cannot be overlooked. With lower ink consumption compared to other methods, businesses can achieve significant savings, especially when producing smaller batches. The ability to quickly shift between different designs and orders further enhances productivity, making DTF a promising solution for evolving market demands. As consumer expectations continue to rise, adapting to these technologies allows businesses to remain competitive and responsive.

Exploring DTG Printing Innovations

Direct-to-Garment (DTG) printing leverages advanced inkjet technologies to produce highly detailed prints directly onto fabric surfaces. This method’s strength lies in its capability to handle vibrant and intricate designs with unprecedented precision, making it the preferred choice for custom orders or fashion lines that require standout graphics. DTG is especially effective when used on cotton or cotton-blend materials, ensuring that the final product possesses a soft, breathable feel while showcasing remarkable color fidelity.

Recent advancements in DTG technology have paved the way for even greater customization possibilities. For instance, new pretreatment solutions and inks are being developed to enhance ink absorption and vibrancy, eliminating some of the traditional bottlenecks in the printing process. This innovation not only improves print quality but also accelerates production timelines, providing businesses with the agility needed to meet fluctuating customer demands while maintaining high quality.

Comparative Analysis: DTF Printing vs. DTG

When comparing DTF printing vs. DTG printing, a few critical factors emerge that can sway business decisions. Quality is often the primary concern; DTG is known for its ability to create exceptional color vibrancy and detail, particularly suited for complex designs. However, DTF has made substantial advancements, allowing it to produce similarly high-quality results across a wider variety of fabrics. This key factor can significantly influence how brands choose to position their offerings in a saturated marketplace.

Additionally, businesses need to pay close attention to cost-effectiveness in the DTF vs. DTG debate. While DTG can become economically viable for high-volume orders due to its streamlined processes, DTF tends to shine in smaller batch productions where ink usage is optimized. A careful assessment of typical print volumes is essential for businesses to determine which method aligns best with their operational strategies and customer expectations.

Fabric Compatibility Considerations

The compatibility of printing methods with different fabrics is a crucial differentiator between DTF and DTG printing. DTF printing offers a distinct advantage in this regard, as it can be applied to a broad spectrum of materials, including cotton, polyester, and blends. This broad versatility allows businesses to satisfy diverse market demands and cater to various customer needs, from sports apparel to fashion garments. Such flexibility can open up new avenues for revenue generation and partnership opportunities.

On the other hand, DTG printing is predominantly limited to cotton fabrics, which might restrict a business’s potential to expand its offerings. While DTG excels in producing stunning results on cotton materials, companies should assess whether their target market primarily favors these fabrics before committing to a solely DTG operation. Understanding the fabric needs of your customer base is fundamental to ensuring that your printing services remain relevant and appealing.

Cost Factors Influencing Your Printing Choice

Budgetary considerations play a pivotal role in the decision-making process when evaluating DTF and DTG printing methods. For businesses focused on cost management, DTF printing often emerges as the more economical solution, particularly for small runs. Thanks to its lower ink usage and reduced setup costs, businesses can maintain profitability while meeting customer demands without overcommitting resources.

In contrast, DTG printing can represent a higher upfront investment due to the need for specialized equipment and pretreatment processes. However, for larger orders with intricate designs, the unique quality that DTG prints deliver may justify the costs. Therefore, businesses are advised to conduct a thorough analysis of their typical order volumes and product offerings to determine which printing method aligns better with their budget and sustainability goals.

Future Outlook for Printing Technologies

As technology progresses, the future landscape of printing solutions is set to evolve significantly, particularly for DTF and DTG methods. Innovations in printing technology, such as advancements in ink formulations, printing heads, and automated processes, will likely lead to improved print quality and operational efficiencies across both techniques. Consequently, businesses that embrace these emerging capabilities can boost their production agility and competitive edge.

Furthermore, integrating both DTF and DTG printing services can prove beneficial for businesses looking to broaden their offerings. By being able to accommodate a diverse range of customer requests—from high-volume production to unique, custom prints—companies can position themselves as versatile printers capable of meeting varied market demands. The key to staying ahead in this industry lies in adaptability, a focus on quality, and a commitment to utilizing the latest technologies.

Frequently Asked Questions

What is the primary difference between DTF printing and DTG printing?

The primary difference between DTF (Direct-to-Film) printing and DTG (Direct-to-Garment) printing lies in their application processes. DTF printing uses a transfer film to apply designs onto fabrics, making it versatile for various materials, while DTG printing directly applies ink onto the garment using specialized inkjet technology, primarily suited for cotton and cotton-blend fabrics.

Which method, DTF printing or DTG printing, offers better image quality for custom designs?

DTG printing typically provides superior image quality and color vibrancy for intricate custom designs due to its direct application onto fabric. However, recent advancements in DTF printing technology are enabling it to produce high-quality results on a wider range of fabric types.

Is DTF printing more cost-effective than DTG printing for small runs?

Yes, DTF printing is often more cost-effective for small runs because it generally uses less ink, resulting in lower production costs. This makes it an attractive option for businesses with lower order volumes, while DTG printing may be more justified for larger quantities with complex designs.

What are the fabric compatibility differences between DTF and DTG printing?

DTF printing has better fabric compatibility as it can work on a variety of materials, including cotton, polyester, and blends. In contrast, DTG printing is primarily suited for cotton and cotton-blend fabrics, which limits its versatility in different fabric types.

Which printing method is faster in terms of production speed, DTF or DTG?

DTF printing generally offers faster production speeds than DTG printing, as it requires less setup time and allows for quick changes between orders. This efficiency is particularly important for businesses needing rapid turnaround times.

Can businesses use both DTF printing and DTG printing to meet customer demands?

Absolutely! Many businesses choose to adopt both DTF and DTG printing methods to cater to diverse customer preferences and maximize revenue potential. By offering both options, businesses can provide high-quality solutions for various types of projects and fabric requirements.

| Aspect | DTF Printing | DTG Printing |

|---|---|---|

| Quality and Detail | Good quality with vibrant colors; closing the gap on detail. | Superior quality and vibrant color for intricate designs. |

| Cost-Effectiveness | More economical for smaller runs; less ink waste. | Higher price point justifiable for complex prints, better for larger orders. |

| Speed and Production Volume | Faster setup and turnaround times; less downtime. | Longer production times due to pre-treatment requirements. |

| Fabric Compatibility | Versatile across various fabric types including cotton and polyester. | Primarily suitable for cotton or cotton blends. |

Summary

DTF printing vs. DTG printing offers businesses essential choices in the realm of modern printing technology. Understanding the nuances between these two methods is vital for any company aiming to maximize its efficiency and customer satisfaction. While DTF boasts adaptability across various fabrics and rapid production capabilities, DTG shines in delivering high-quality, vibrant images suitable for custom orders. Both methods distinctly cater to different needs, emphasizing that businesses should assess their target audience and operational costs carefully. As the printing industry evolves, keeping informed about these technologies will help businesses align their strategies effectively and stay competitive.