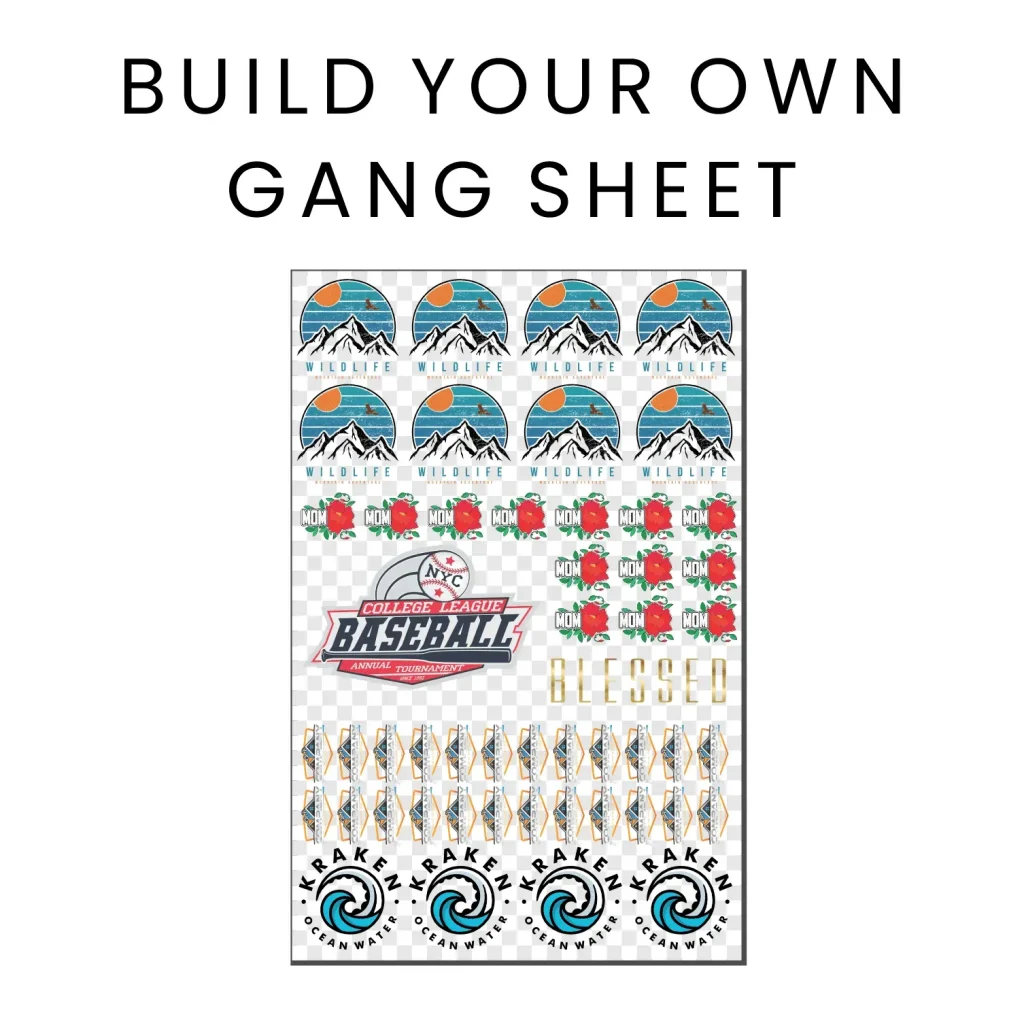

The DTF gangsheet builder is revolutionizing the way businesses approach Direct to Film (DTF) printing, making it a vital tool for enhancing production efficiency. As the printing industry becomes increasingly competitive, integrating smart printing solutions is essential for staying ahead. By employing innovative DTF printing techniques, users can create optimized gang sheets that maximize material use and output quality. This technology streamlines the entire workflow, helping operators reduce costs and turnaround times significantly. Dive into the world of DTF gangsheet builders and discover how they can transform your printing operations into a model of efficiency and quality.

In the realm of DTF printing, utilizing a gangsheet optimizer can drastically improve overall production workflows. This advanced tool streamlines the process of combining multiple designs into singular print jobs, facilitating efficient resource management and cost reduction. Companies seeking to enhance their printing capabilities often turn to smart solutions like these to integrate various printing techniques seamlessly. With an eye on effective gangsheet techniques, businesses can achieve higher-quality outputs while maintaining an organized and efficient printing environment. Embrace the potential of gangsheet technologies to elevate your printing operations and stay competitive.

The Benefits of Efficient Gangsheet Optimization

Gangsheet optimization plays a crucial role in the DTF printing industry, helping businesses streamline their workflow and maximize output. By efficiently arranging designs on a single sheet, printers can significantly reduce material waste and costs associated with repetitive setups. The organized layout enables a seamless transition from design to printing, ultimately elevating production efficiency. Additionally, utilizing gang sheets not only conserves resources but also enhances the quality of prints by allowing for better color accuracy and alignment.

Furthermore, optimized gang sheets can lead to faster turnaround times, which is essential for meeting customer demands in a competitive market. Print shops that leverage gangsheet optimization gain a unique advantage; they can take on multiple orders and fulfill them quickly, thereby increasing their bottom line. With advanced gang sheet builder tools, users can easily create layouts that balance design aesthetics with production capabilities, ensuring maximum utilization of both time and raw materials.

Selecting High-Quality Materials for Enhanced DTF Printing

The importance of material selection in DTF printing cannot be overstated. High-quality inks not only enhance the vibrancy of colors but also ensure a stronger bond between the transfer film and fabric. Choosing inks that are compatible with your specific printing equipment is paramount; it influences the overall print quality as well as the longevity of the designs. Quality inks reduce the chances of smudging or fading, allowing customers to enjoy durable and visually striking prints.

Moreover, the choice of transfer film is just as critical. Not all films are created equal; some are designed to work best with certain types of inks, which can significantly affect the print results. By investing in the right transfer materials tailored to your specific DTF printing technique, you streamline your printing workflow and minimize the need for adjustments or corrections during production. This careful selection contributes to overall efficiency by reducing waste and ensuring quick, high-quality outputs.

Leveraging Advanced Printing Techniques for Optimal Efficiency

Advanced printing techniques can fundamentally change the efficiency of your DTF production processes. Utilizing features such as dual-ink systems allows for the simultaneous printing of multiple colors, which can dramatically reduce production times. This innovation is particularly beneficial for high-volume jobs, as it maximizes the output per hour and meets the fast demands of the market, giving businesses a competitive edge.

Additionally, adjusting speed settings can optimize your efficiency without sacrificing quality. Understanding the delicate balance between speed and print accuracy empowers you to tweak your printing processes according to specific job requirements. For instance, during critical jobs where every detail matters, slowing down to ensure a high-quality print can be more beneficial than opting for rapid but potentially flawed outputs.

Pre-Press Adjustments: A Step Towards Quality Control

Pre-press adjustments are essential for ensuring that your DTF prints achieve optimal quality and efficiency. Conducting test prints before the main production run allows for fine-tuning of colors, alignment, and overall design accuracy. This practice not only reduces the likelihood of large-scale errors but also saves valuable time and resources, reinforcing the importance of a diligent pre-press stage in the workflow.

Regular calibration of printers is another critical aspect of pre-press adjustments. It ensures that machines operate at their best, producing consistent results across all print jobs. Proper calibration minimizes discrepancies in print quality, which can lead to costly corrections later in the process. Implementing these pre-press steps guarantees a smoother workflow and instills a commitment to high-quality outputs that meet client expectations.

Post-Processing Techniques: Ensuring Durability and Quality

Post-processing techniques are essential to ensure the longevity and quality of DTF prints. Proper curing methods, such as using heat presses or curing ovens, strengthen the adhesive bond between the print and fabric, making the final product resilient against wear and tear. Engaging in meticulous post-processing not only preserves the vibrancy of the colors but also extends the life of the prints, benefiting both the printer and their customers.

Incorporating stringent quality control measures after each print job is equally important. Performing thorough quality checks verifies that every design meets the established standards before reaching customers. This practice enhances customer satisfaction and builds trust in your brand, as clients will appreciate the consistency and reliability of your work. By committing to effective post-processing techniques, you solidify your reputation in the competitive DTF printing market.

Conclusion: Streamlining Your DTF Printing Strategy

In summary, enhancing production efficiency in DTF printing is a multifaceted approach that requires attention to detail at every stage of the process. From optimizing gang sheets to selecting high-quality materials and employing advanced printing techniques, the commitment to maximizing efficiency can lead to significant cost savings and improved print quality. Each element of the workflow interconnects, and refining these processes promotes operational excellence.

Finally, staying informed about the latest advancements in smart printing solutions and DTF technology keeps your business competitive. Adopting innovations and continuously seeking methods to optimize your printing workflow will not only elevate your printing capabilities but will also enhance customer satisfaction by providing high-quality products in a timely manner.

Frequently Asked Questions

What benefits does the DTF gangsheet builder bring to printing efficiency?

The DTF gangsheet builder significantly boosts production efficiency by allowing multiple designs to be printed in one job. This optimization of material usage reduces costs and minimizes waste, ensuring that printers can achieve a high output without sacrificing quality.

How can I optimize gangsheet layout for my DTF printing operations?

Optimizing gangsheet layout involves careful planning using graphic design software like Adobe Illustrator. By arranging designs strategically on a single gang sheet, you maximize the print area of your transfer film, which leads to enhanced efficiency and lower production costs.

What types of materials are recommended for effective DTF gangsheet printing?

For efficient DTF gangsheet printing, it’s crucial to select high-quality inks and specialized transfer films. Quality inks provide vibrant colors and better adhesion, while transfer films tailored for specific inks can significantly improve overall production efficiency and print quality.

What advanced printing techniques can be used with a DTF gangsheet builder?

Implementing advanced printing techniques, such as using dual-ink systems, can enhance workflow efficiency. This allows for simultaneous printing of different colors, decreasing turnaround time significantly and making it ideal for high-demand environments.

Why are pre-press adjustments critical in DTF gangsheet building?

Pre-press adjustments are vital for DTF gangsheet building as they set the foundation for a successful print run. Conducting test prints and regular printer calibration ensure color accuracy and alignment, which minimizes the risk of errors during production.

What post-processing steps should be taken after using a DTF gangsheet builder?

After employing a DTF gangsheet builder, effective post-processing steps include ensuring proper curing of printed films and conducting thorough quality checks. These actions help achieve durable prints that withstand wear while maintaining high production standards.

| Key Points | Details |

|---|---|

| Understanding the Power of Gang Sheets | Gang sheets combine multiple designs into one print job, optimizing material usage and saving time. |

| Layout Planning | Use software like Adobe Illustrator for efficient arrangement on the gang sheet. |

| Spacing Management | Ensure adequate spacing to prevent misprints and waste. |

| Selecting the Right Materials | Quality materials are crucial for achieving optimal results in DTF printing. |

| Ink Quality | Invest in high-quality DTF inks for vibrant colors and durability. |

| Transfer Film | Choose transfer films that are compatible with your inks for best results. |

| Leveraging Advanced Printing Techniques | Implement advanced techniques to significantly enhance efficiency. |

| Dual-Ink Systems | Utilize printers that can print multiple colors simultaneously to reduce time. |

| Speed Settings | Find the right balance between print speed and quality. |

| Pre-Press Adjustments for Better Results | Pre-press steps are crucial for maintaining efficiency and quality. |

| Test Prints | Conduct test prints to ensure color and design accuracy before production. |

| Calibration | Regularly calibrate printers to ensure optimal output and minimize errors. |

| Implementing Post-Processing Techniques | Post-processing steps are essential for quality assurance after printing. |

| Curing | Proper curing of films is vital for adhesive bonding and durability. |

| Quality Control | Perform quality checks post-printing to maintain high standards. |

Summary

The DTF gangsheet builder significantly enhances your production efficiency by integrating effective techniques and practices throughout the printing process. By utilizing smart gangsheet-building strategies, you can optimize your workflow, reduce material wastage, and improve the quality of your prints. Understanding the nuances of layout planning, selecting high-quality materials, leveraging advanced printing techniques, and committing to thorough pre- and post-press procedures are all vital steps in maximizing your DTF efficiency. Embracing these practices not only helps in managing costs but also boosts overall output quality, making you a formidable player in the DTF printing industry.