In the bustling realm of custom printing, the DTF Gangsheet Builder stands out as a revolutionary tool designed to enhance print efficiency and output. This innovative system allows businesses to streamline the DTF (Direct to Film) printing process by combining multiple designs into a single gang sheet, significantly minimizing waste and maximizing production potential. With DTF printing becoming increasingly popular for its vibrant color transfers on various fabrics, mastering the Gangsheet Builder is essential for setting your printing business apart from the competition. By leveraging this advanced technique, you not only boost your printing production but also ensure quality consistency in each transfer. Join us as we delve into effective printing production tips that will harness the full capabilities of the DTF Gangsheet Builder to elevate your operations.

Custom apparel decoration has entered a new era with the emergence of advanced tools like the DTF Gangsheet Builder, enabling users to optimize their workflow in the world of textile printing. This method simplifies the incorporation of multiple designs on a single transfer sheet, allowing for greater resource efficiency and reduced operational costs in the printing landscape. Utilizing such gang sheets in the Direct to Film printing process enhances both quality and productivity, providing a competitive edge for businesses in the printing sector. Whether you refer to it as DTF printing or simply garment decoration, employing effective strategies can significantly impact your production capabilities. Let’s explore the underlying concepts and practical solutions that can further amplify your printing efforts.

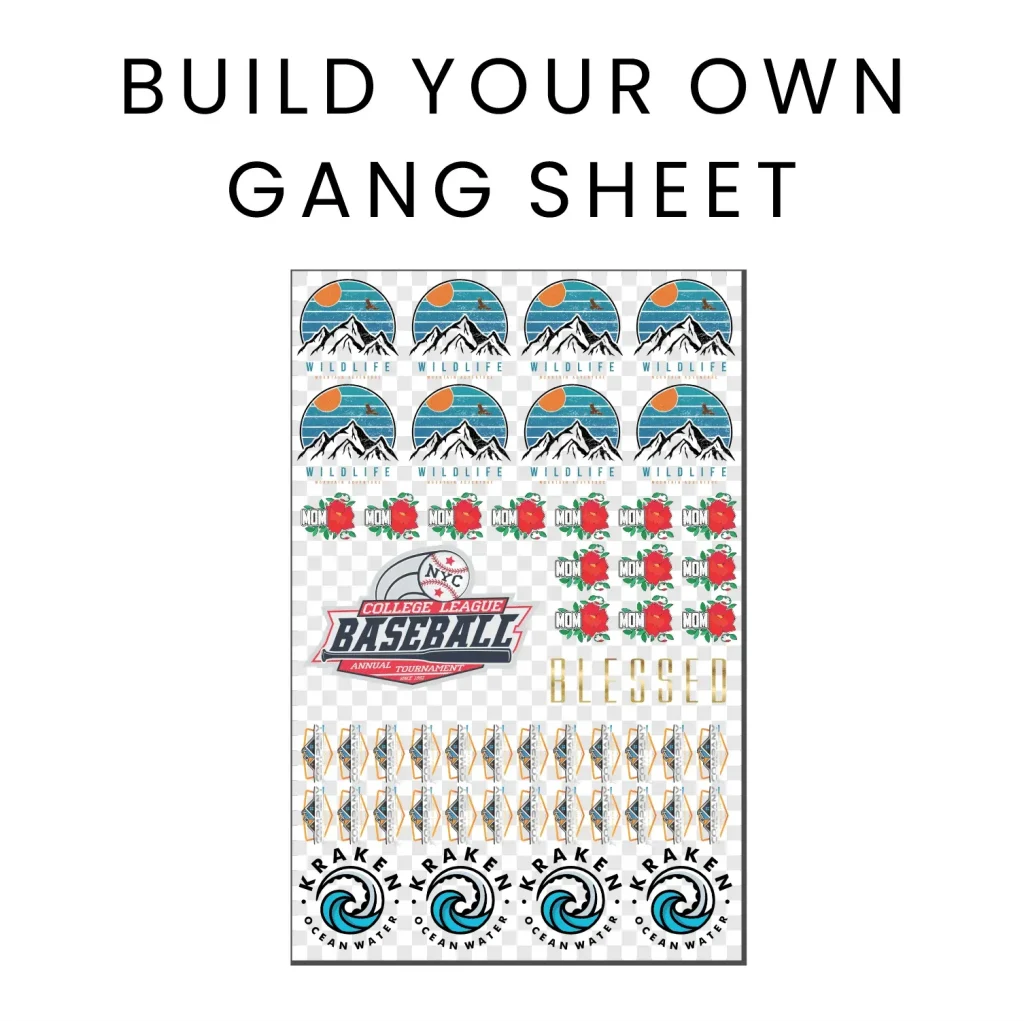

Maximizing Efficiency with the DTF Gangsheet Builder

The DTF Gangsheet Builder is a revolutionary tool that streamlines the printing process, allowing businesses to maximize their output while minimizing waste. By combining multiple designs into a singular transfer, printers can effectively reduce the amount of film used, thus decreasing costs and increasing production efficiency. This innovative approach not only saves on material costs but also drastically cuts down the time required for individual print setups, making it an essential feature for any printing business looking to enhance efficiency.

Another advantage of using the DTF Gangsheet Builder is the ability to produce high-quality prints without sacrificing speed. By optimizing the layout of designs on the gang sheet, printers can ensure that each transfer is utilized effectively, further boosting print efficiency. This method allows for quick alterations and adjustments, enabling the printing process to adapt to last-minute requests or changes, which is crucial in a fast-paced printing environment.

Understanding the Essentials of DTF Printing

DTF printing technology represents a significant advancement in the world of custom garment decoration, allowing for high-resolution prints on various fabrics. It is essential for printing businesses to grasp the fundamentals of DTF to fully leverage its potential. The process involves printing designs onto a specialized film, which is then heat-transferred onto the fabric. This method is celebrated for its vibrancy and durability, making it a preferred choice for many printing applications, from t-shirts to sportswear.

To succeed in DTF printing, companies must focus on using advanced materials and equipment. The quality of the DTF ink and transfer films plays a critical role in achieving desirable print results. High-quality inks not only enhance the vibrancy of designs but also improve adhesion to fabrics, resulting in long-lasting prints. Therefore, investing in premium materials is a critical step for printers seeking to deliver high-quality products.

Leveraging Automation for Enhanced Printing Production

In today’s digital age, automation in printing production is no longer a luxury but a necessity. Automated systems, including printers and heat presses, significantly increase the speed and consistency of output. By reducing human error and manual labor requirements, businesses can streamline their workflows and boost overall production efficiency. Integrating these machines with software solutions can further enhance the printing process by allowing for real-time adjustments and monitoring.

Furthermore, employing automation not only results in higher output but also aids in maintaining quality control. Automated machines often come equipped with features that ensure accurate temperature and pressure during the printing process, which are vital for achieving optimal results. As automation technology continues to evolve, printing companies that embrace these advancements will find themselves at a competitive advantage.

The Importance of Regular Printer Maintenance

Regular maintenance is a crucial aspect of keeping printing production running smoothly and efficiently. Printers that are well-maintained operate at optimal levels, reducing the likelihood of breakdowns that can disrupt workflow. Simple tasks such as cleaning print heads, checking ink levels, and ensuring that heat presses are functioning efficiently can go a long way in preventing costly repairs and downtime. Scheduling regular upkeep is essential in prolonging the lifespan of your printing equipment.

Additionally, proactive maintenance measures can lead to significant improvements in print quality. A printer that is clean and calibrated properly will produce clearer, more vibrant designs, which are essential for satisfying customer expectations. By dedicating time to maintain equipment, printing businesses not only enhance operational efficiency but also ensure that they consistently deliver high-quality products to their clients.

Implementing Effective Quality Control Processes

Establishing a robust quality control process is vital for any printing business hoping to maintain a high standard of output. Regular inspections of printed items before they are dispatched help catch any errors that could lead to customer dissatisfaction. This includes checking for color fidelity, alignment, and overall print quality. By catching issues early in the production process, businesses can avoid wasting both time and resources on reprints.

Moreover, instituting test runs for new designs is a crucial element of quality control in DTF printing. Conducting these trials not only allows for the verification of color accuracy and design execution but also offers an opportunity to refine techniques and processes. Implementing a culture of quality control ensures that every aspect of printing meets the established standards, reinforcing the company’s commitment to excellence.

Staying Ahead with Industry Trends in Printing

The printing industry is constantly evolving, with new trends, technologies, and techniques emerging regularly. Staying informed about these changes is essential for businesses aiming to remain competitive. By subscribing to industry publications, attending trade shows, and participating in networking events, printers can glean valuable insights into the latest advancements in DTF printing and related technologies.

Incorporating the latest trends not only aids in boosting production efficiency but also helps businesses adapt to shifting customer demands. Whether it’s utilizing upgraded printing equipment or adopting new design software, being proactive in staying current opens up opportunities for enhancing quality and expanding service offerings. Competitors who neglect industry trends may risk falling behind, making it critical for printing businesses to stay engaged with market developments.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a tool that allows printers to create gang sheets, combining multiple design prints onto a single transfer film. This method enhances DTF printing by maximizing material usage, minimizing waste, and improving print efficiency, thereby leading to higher output and cost savings.

How can I optimize my design layouts using the DTF Gangsheet Builder?

To optimize design layouts with the DTF Gangsheet Builder, utilize design software that supports gang sheet creation. Arrange multiple designs efficiently, ensuring proper alignment and spacing, which maximizes the number of prints per transfer. This will significantly boost your print efficiency and production output.

What are the benefits of using gang sheets in DTF printing?

Using gang sheets in DTF printing offers several benefits, including reduced material waste, lower printing costs, and increased production speed. By grouping designs together, printers can streamline their workflow, leading to a more efficient printing process and better overall results.

What materials are essential for effective DTF printing with the Gangsheet Builder?

To achieve effective DTF printing using the Gangsheet Builder, it’s crucial to invest in high-quality DTF inks and transfer films. These materials contribute to vibrant prints, durability, and fewer printing errors, ultimately enhancing your print quality and efficiency.

How can automation improve the efficiency of DTF printing production with gang sheets?

Automation significantly boosts DTF printing production by streamlining processes such as printing and heat pressing. Automated machines reduce manual labor and increase consistency in output, allowing businesses to maximize their productivity and meet demand more effectively when working with gang sheets.

What quality control processes are recommended when using the DTF Gangsheet Builder?

Implementing a quality control process when using the DTF Gangsheet Builder involves regular inspections of prints to ensure they meet quality standards. Conduct test runs and track error rates to identify recurring issues, ensuring that the production maintains high quality and efficiency.

| Key Points | Details |

|---|---|

| Introduction | Importance of efficiency and quality in custom printing; DTF Gangsheet Builder helps optimize production. |

| Understanding DTF Printing | DTF printing is effective for vivid designs on various fabrics, using heat to transfer images from a special film. |

| What is a Gangsheet? | A method of combining multiple designs into one transfer sheet to maximize material usage and reduce waste. |

| Optimize Design Layout | Use software for gang sheet creation to arrange multiple designs efficiently, ensuring aligned and high-quality prints. |

| Select High-Quality Materials | Investing in premium inks and films enhances print quality and reduces printing errors. |

| Leverage Automation | Automated systems improve efficiency, reduce manual labor, and create a seamless workflow between printing and heat pressing. |

| Perform Regular Maintenance | Consistent maintenance is essential for preventing breakdowns and ensuring high production quality. |

| Implement Quality Control Processes | Regular inspections and test runs can ensure quality standards are met, minimizing errors during production. |

| Conduct Test Prints | Test prints verify color accuracy and design transfer before large production runs. |

| Train Your Staff | Training improves staff handling of DTF printers and presses, enhancing overall production quality. |

| Stay Updated with Industry Trends | Integrating new tools and methods keeps production efficient and improves quality. |

Summary

DTF Gangsheet Builder is a powerful tool that can revolutionize the way your printing business operates. By implementing strategies such as optimizing design layouts, selecting superior materials, and automating production processes, you can greatly enhance your output and ensure superior quality in your prints. In addition, regular maintenance and quality control are crucial to maintaining high standards, while training your staff and staying updated with industry advancements will keep your business competitive. Embrace the potential of the DTF Gangsheet Builder to lead your business towards unprecedented success in the custom printing market.