The DTF Gangsheet Builder is revolutionizing the way enthusiasts create custom apparel with Direct to Film (DTF) printing. As a crucial tool for maximizing print efficiency, it allows users to arrange multiple designs on a single sheet, which is especially beneficial for beginners. By understanding DTF printing best practices and utilizing the gangsheet builder, newcomers can seamlessly navigate their creative process, transforming fabric into vibrant masterpieces. This guide delves into essential heat transfer printing tips and the most effective DTF printing materials to enhance your results. As we explore beginner DTF techniques, you’ll discover the opportunities that this innovative tool presents in the world of custom design.

In the realm of custom clothing creation, tools like the DTF Gangsheet Builder empower designers to optimize their output while exploring various design possibilities. Direct to Film printing, celebrated for its versatility, combines artistry and technology to yield stunning fabric prints that resonate with creativity. The gangsheet printing method not only enhances material efficiency but also promises consistent quality in each design. As we delve into the intricacies of this process, it becomes clear that understanding key principles, from beginner DTF techniques to heat transfer printing tricks, is crucial for crafting successful and durable apparel. Embrace the endless potential that arises from mastering these contemporary printing practices.

The Basics of DTF Printing for Beginners

DTF (Direct to Film) printing is an innovative technology that has reshaped the landscape of custom apparel. This printing method allows users to print vibrant designs on a special film that can then be transferred to various fabrics. For beginners venturing into DTF, it’s essential to understand the basics, including how DTF printing differs from traditional heat transfer methods and the various DTF printing materials available. By grasping these fundamentals, newcomers can avoid common pitfalls and produce high-quality prints from the onset.

One of the key advantages of DTF printing is its versatility. It works well on a variety of materials, including cotton, polyester, and blends. Furthermore, the ability to print intricate designs with vivid color reproduction means that your creations can stand out. Beginners should take time to familiarize themselves with the types of inks and films used in DTF printing, as the choice of materials plays a critical role in the final appearance and durability of printed designs.

Mastering the DTF Gangsheet Builder for Optimal Design

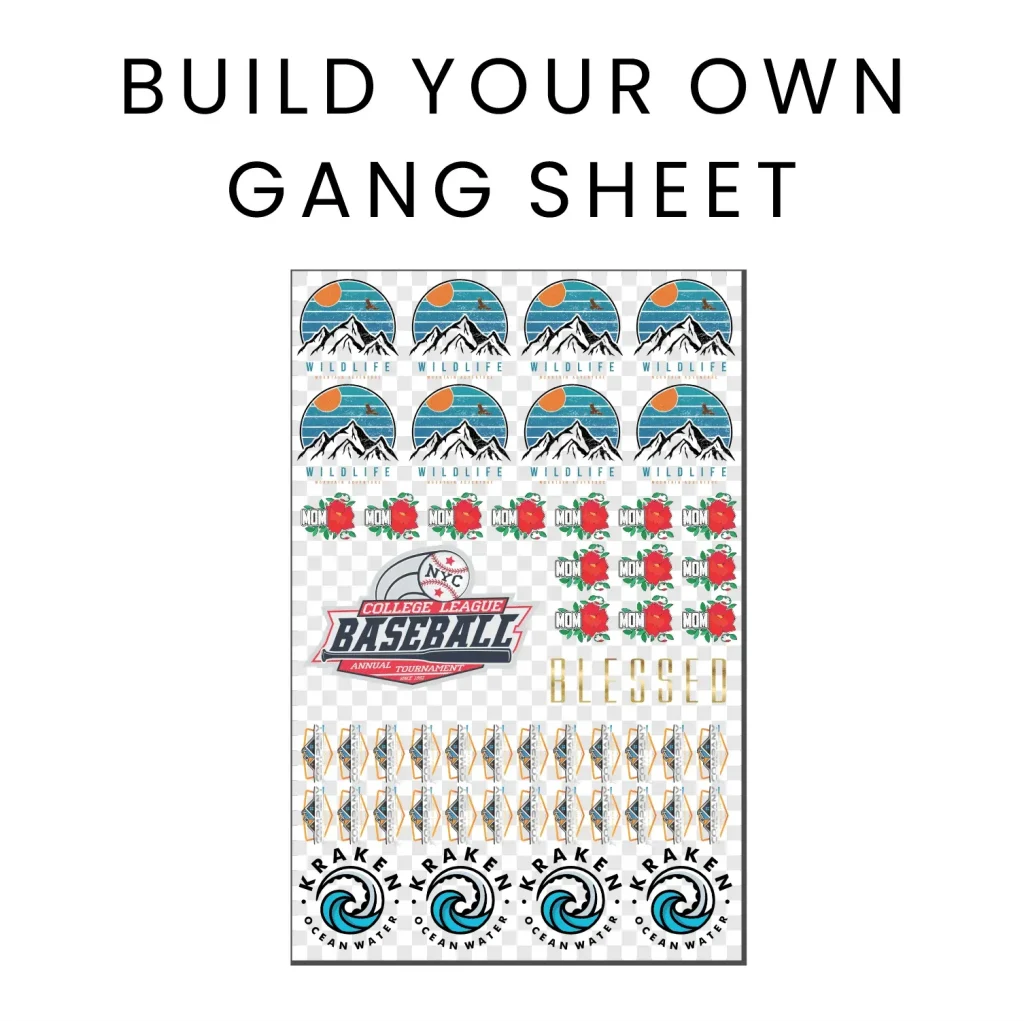

The DTF Gangsheet Builder is an essential tool for maximizing the efficiency of your printing process. This feature enables users to arrange multiple designs on a single film sheet, minimizing waste and reducing costs. For those new to DTF printing, mastering the Gangsheet Builder is crucial. It allows for quicker production times and helps ensure that designs are layered correctly to prevent color bleeding during the transfer process, leading to a more professional finish.

Using the Gangsheet Builder correctly involves understanding how to lay out your designs strategically. Beginners should focus on keeping designs adequately spaced and properly sized to fit the printable area. Incorporating LSI keyword strategies such as optimizing gangsheet printing layouts will not only improve the user’s proficiency but also enhance the overall quality of the final printed product. Experimenting with different layouts can yield valuable insight into personal preferences and printing capabilities.

Top DTF Printing Materials You Should Consider

Selecting the right DTF printing materials is fundamental for achieving high-quality prints. Beginning with high-quality films specifically designed for DTF printing ensures clear and vibrant transfers. Moreover, using compatible inks that adhere well to these films can dramatically affect the outcome of your designs. Beginners should invest in reputable brands that offer reliable products to prevent issues such as ink bleeding or fading after washing.

Additionally, understanding the various fabric types and their compatibility with DTF printing is essential for anyone looking to expand their custom printing repertoire. Different materials, from cotton t-shirts to polyester blends, may react uniquely to the heat transfer process. By exploring the spectrum of DTF printing materials and conducting test prints, beginners can identify the best combinations for their specific projects.

Printer Settings for Successful DTF Printing

When it comes to DTF printing, configuring the right printer settings is paramount to achieving professional results. Each printer may have specific requirements, which necessitates understanding the media type settings. Adjusting the printer to accommodate the thickness and texture of the DTF film can significantly influence the print quality. Beginners should pay close attention to the recommended print quality settings, as opting for ‘high’ quality will often yield sharper and more detailed designs.

It’s also important to periodically revisit and fine-tune printer settings, especially when switching between different materials or colors. As the DTF printing landscape evolves, manufacturers may recommend new settings to enhance print outcomes. By staying up-to-date with these recommendations, beginners can ensure that their prints maintain consistency and vibrancy across various projects.

Pre-Treating Fabrics for Enhancing Adhesion

Pre-treatment of fabrics is a critical step that many beginners often overlook. This process enhances the adhesion of DTF prints, particularly on synthetic materials, which may require a specific pre-treatment solution. By applying the correct pre-treatment, you ensure that the print adheres firmly to the garment, reducing the risk of peeling or fading over time. Beginners should always refer to the manufacturer’s guidelines on which fabrics necessitate pre-treatment and the best practices for applying it.

Moreover, experimenting with different pre-treatment solutions can help you understand how various fabrics respond to DTF printing. Conducting tests on sample pieces can provide insights into the ideal application methods and quantities needed for optimal adhesion. The effort put into pre-treating fabrics will pay off, leading to more durable and long-lasting prints that meet the quality expectations of your customers.

Heat Transfer Techniques for Effective Application

Heat transfer techniques are pivotal in DTF printing, as proper heat application directly affects print quality. Beginners should familiarize themselves with the right temperature settings, which typically hover around 320°F (160°C) for most fabrics. Inconsistent temperature can lead to subpar transfers, and understanding the heat profile of your press is critical. Additionally, using a good heat press with accurate temperature controls will make a significant difference in the outcome.

Timing is another crucial factor in the heat transfer process. Ensuring that the transfer time falls within the recommended range of 10-15 seconds can prevent under or over-transfers, which can affect the print’s longevity and vibrancy. Beginners should utilize a test fabric to establish the best conditions for their specific machine, as each heat press may require slight adjustments based on its efficiency and the type of material being used.

Frequently Asked Questions

What are the best practices for beginners using the DTF Gangsheet Builder?

Beginners should focus on choosing high-quality DTF printing materials, mastering the gangsheet arrangement by keeping designs within the printable area, and utilizing simple color palettes for cohesive looks. Additionally, adjusting printer settings, pre-treating fabrics as necessary, and conducting test transfers can significantly improve the printing experience with the DTF Gangsheet Builder.

How do I ensure quality prints when using the DTF Gangsheet Builder?

To ensure quality prints with the DTF Gangsheet Builder, select reputable DTF films and inks. It’s essential to adjust your printer settings, pre-treat fabrics for better adhesion, and perfect your heat transfer parameters, including temperature, timing, and pressure for optimal results.

What is the DTF printing process and how does the Gangsheet Builder enhance it?

The DTF printing process involves printing designs on a special film, which is then transferred onto fabric using heat and pressure. The DTF Gangsheet Builder enhances this by allowing users to efficiently arrange multiple designs on a single sheet, maximizing material usage and reducing waste.

What should I consider regarding printer settings for DTF printing?

When using the DTF Gangsheet Builder, select the appropriate media type and ensure your print quality setting is on high. These adjustments are crucial for capturing the details of your artwork effectively on the DTF film.

Why is pre-treating fabrics important in DTF printing?

Pre-treating fabrics can significantly improve the adhesion of DTF prints, especially on synthetic materials. This step is essential for achieving vibrant and long-lasting prints when using the DTF Gangsheet Builder.

How can I improve my DTF printing techniques as a beginner?

To improve your DTF printing techniques, experiment with different designs and settings, conduct test transfers on scrap fabrics, and regularly maintain your printer and heat press equipment. Staying engaged with DTF printing communities can also provide valuable insights and learning opportunities.

| Best Practices for DTF Gangsheet Builder | |

|---|---|

| Introduction to DTF Printing | DTF printing is a method for customizing apparel, utilizing films transferred to fabric. |

| Choosing Quality Materials | Using quality DTF films and inks ensures sharp output and durability. |

| Mastering Gangsheet Arrangement | Keep designs within printable boundaries and use simple color palettes. |

| Printer Settings | Adjust media type and print quality settings for optimal results. |

| Pre-Treating Fabrics | Pre-treatment enhances adhesion, especially on synthetic fabrics. |

| Perfecting Heat Transfer | Set transfer temperature to 320°F (160°C) for 10-15 seconds. |

| Testing Is Key | Conduct test transfers to evaluate quality before large runs. |

| Maintenance of Equipment | Regularly clean and calibrate printer and heat press machines. |

| Embrace Experimentation | Experiment with different settings and designs to find best practices. |

| Continue Learning | Follow communities and resources for ongoing DTF printing education. |

Summary

DTF Gangsheet Builder is an essential tool for designers looking to create custom apparel efficiently. By familiarizing yourself with DTF printing and its best practices, such as selecting high-quality materials and mastering the arrangement of designs, you can greatly enhance your crafting experience. Regular testing and maintenance of your equipment further ensure that your output is of the highest quality. Embrace a mindset of experimentation and continuous learning, as this will pave the way for you to evolve into a skilled DTF printing professional, capable of producing impressive and lasting designs.