DTF transfers, or Direct-to-Film transfers, are revolutionizing the fabric printing industry with their impressive versatility and quality. This innovative fabric printing technology is gaining traction among custom apparel producers, offering a cost-effective solution that doesn’t compromise on details or colors. With the ability to print intricate designs onto a variety of fabrics, DTF printing opens up endless possibilities for creative expression in clothing and merchandise. As sustainability becomes increasingly important in current manufacturing practices, DTF transfers also leverage eco-friendly inks, further enhancing their appeal. Join us as we explore how this cutting-edge process is shaping the future of personalized fabric printing and redefining the landscape of custom apparel.

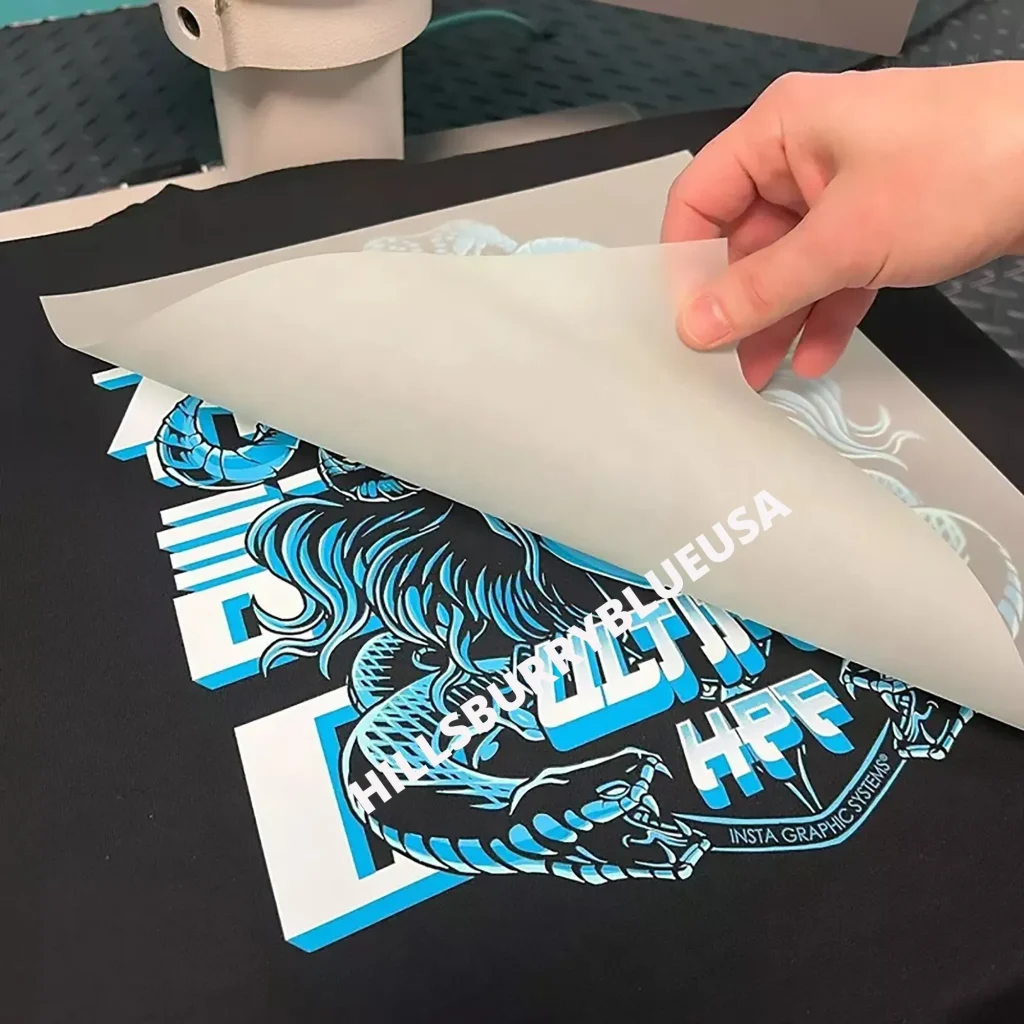

Known also as Direct-to-Film printing, this technique represents a major advancement in fabric transfer methods. By applying designs directly onto a special film and then transferring them onto various textiles, this approach marries the advantages of both traditional and modern printing technologies. Custom designs, vibrant colors, and durability are hallmarks of this innovative printing method, making it an attractive option for businesses focused on sustainable printing practices. As we delve deeper into the topic, you’ll discover how DTF printing not only influences the current market but also meets the growing demand for bespoke apparel solutions.

Exploring the Versatility of DTF Transfers

DTF transfers offer remarkable versatility in the fabric printing realm, enabling businesses to adapt to a variety of textile types seamlessly. This printing method can easily be applied to materials such as cotton, polyester, blends, and even specialty fabrics like nylon and leather. This adaptability allows custom apparel brands to expand their product ranges without the need for multiple printing methods. Consequently, businesses can produce everything from t-shirts and hoodies to sportswear and promotional items, all while maintaining high quality and attention to detail.

In today’s fashion landscape, where trends can change rapidly, the ability to work with diverse fabrics sets DTF printing apart as a preferred choice for many entrepreneurs. Utilizing a straightforward heat application process, businesses can fulfill orders with precision, offering unique designs that resonate with customer demands for individuality and style. The versatile nature of DTF technology aligns perfectly with evolving consumer preferences and reinforces why it has become a staple in the custom apparel industry.

High-Quality Prints Through DTF Technology

One of the standout features of DTF printing is its capacity to produce high-quality prints that rival traditional printing methods. DTF transfers utilize a unique film that captures intricate designs in vibrant color. Once the film is printed with eco-friendly inks and heat pressed onto the fabric, the result is stunning imagery that boasts clarity and vividness. This ability to replicate fine details makes DTF ideal for businesses focusing on detailed artwork and graphics in their custom apparel offerings.

Moreover, the durability of the prints achieved through DTF technology is noteworthy. These prints are designed to withstand regular wear and tear, making them perfect for everyday clothing. The advanced ink formulations used in DTF ensure these prints maintain their quality through multiple washes, thus minimizing the risk of fading or peeling. As a result, businesses can confidently offer products that meet customer expectations for quality and longevity, setting them apart in a crowded market.

Cost-Effectiveness: A Game Changer for Businesses

One of the most appealing aspects of DTF printing is its cost-effectiveness, particularly for small and medium-sized businesses that may have limited budgets. The initial investment in DTF printing technology is significantly lower compared to Direct-to-Garment (DTG) printing setups and traditional screen printing processes. This affordability allows new businesses to enter the custom apparel market with minimal financial barriers, enabling them to compete effectively without sacrificing print quality.

Additionally, DTF printing reduces waste associated with traditional methods, such as excess ink usage and the need for multiple screens for varying designs. As businesses grow and expand their offerings, the ability to manage costs while maintaining product quality becomes even more crucial. DTF technology benefits entrepreneurs by allowing them to keep their operational costs low while offering a competitive selection of diversified and customizable apparel.

Sustainable Printing Solutions in DTF Transfers

Sustainability in fabric printing has become a non-negotiable for many modern consumers and businesses, and DTF printing method champions this cause effectively. Utilizing eco-friendly inks and advancements in biodegradable films, DTF printing mitigates harmful environmental impacts traditionally associated with fabric production. This responsible approach to printing not only satisfies the growing demand for sustainable practices but also enhances brand reputation in an industry where consumers increasingly value eco-consciousness.

In addition to the materials used, DTF technology enhances sustainability through its efficient printing process. Unlike other method that may involve greater chemical waste or energy intensive production techniques, DTF offers a streamlined operation that reduces overall resource consumption. As businesses adopt DTF transfers, they position themselves as forward-thinking brands committed to environmental stewardship, making them more attractive to a conscious consumer base looking for sustainable options.

Recent Innovations in DTF Printing Technology

The evolution of DTF printing is fueled by continuous technological advancements, substantially altering the landscape of fabric printing. Recent innovations have introduced compact, high-speed printers designed specifically for small and medium-sized enterprises. These instruments boast capabilities that enable quicker production times, allowing businesses to respond to customer demands with impressive speed and efficiency. A quicker turnaround not only enhances customer experience but also improves business agility in today’s fast-paced retail environment.

Furthermore, ongoing research and development efforts are yielding new formulations for inks and films that enhance print quality and durability. This evolving landscape suggests that as more businesses adopt DTF transfers, we can expect even superior print outputs and operational efficiencies. Not only do these innovations reduce production time, but they also open new avenues for creative designs and customization options, further solidifying DTF’s presence as a leading print technology in the fabric printing industry.

Challenges of Implementing DTF Technology

Despite the many advantages associated with DTF printing, businesses may encounter challenges when implementing this technology. For those transitioning from established methods like screen printing or DTG, a significant learning curve can exist. Understanding the nuances of the DTF process, including proper application techniques and maintenance of equipment, requires time and investment in training, which can be daunting for new entrants in the market.

Additionally, while DTF printing presents a lower long-term cost structure, the initial setup, including purchasing a quality printer, films, and inks, can still pose a financial hurdle for some businesses. This initial investment, while often justified through increased efficiency and capacity for customizable products, may deter some entrepreneurs waiting for guaranteed returns. Nonetheless, many businesses that persist and embrace DTF technology find that the long-term benefits far outweigh these initial challenges.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a cutting-edge fabric transfer method. It involves printing a design onto a special film, which is then applied to various fabric types using heat and pressure. This process allows for high-resolution and vibrant prints, making it an ideal choice for custom apparel.

What are the advantages of using DTF transfers for fabric printing?

DTF transfers offer several key advantages, including versatility to print on various materials, high-quality and durable prints that withstand washing, cost-effectiveness due to low startup costs, and a more sustainable printing option with eco-friendly inks.

Is DTF printing suitable for small businesses producing custom apparel?

Yes, DTF printing is particularly ideal for small businesses. Its low cost of entry, high-quality output, and versatility make it a feasible choice for companies looking to produce custom apparel without the significant investment required by traditional methods.

How do DTF transfers compare to other fabric printing methods?

DTF transfers combine the benefits of DTG printing and screen printing while reducing their drawbacks. Unlike DTG, DTF can handle complex designs and is suitable for multiple fabric types, whereas screen printing can be less cost-effective for small runs.

What recent developments are influencing the DTF printing market?

Recent advancements in DTF technology include the introduction of compact and affordable printers designed for smaller businesses. Additionally, increased market demand for unique, customizable apparel is driving growth in the DTF sector, presenting new opportunities for businesses.

What challenges should businesses consider when adopting DTF printing technology?

While DTF printing offers numerous benefits, businesses may face challenges such as a learning curve if transitioning from traditional methods and initial setup costs related to acquiring quality DTF printers and supplies. Addressing these challenges is essential for successful implementation.

| Key Point | Details |

|---|---|

| DTF Printing Method | Utilizes transfer film for high-resolution designs on various fabrics including cotton and polyester. |

| Benefits of DTF | Versatile, produces high-quality and durable prints, cost-effective with affordable setup, and supports sustainability. |

| Recent Developments | Increased popularity, compact printers developed for small businesses, and significant market demand growth. |

| Challenges | Some learning curve for new users and initial setup costs can be a barrier. |

Summary

DTF transfers are revolutionizing the fabric printing industry by offering a modern, efficient, and sustainable option for businesses. As this technology evolves, its versatility and ability to produce vibrant, high-quality designs make it a favored choice in custom apparel. Understanding DTF transfers enables businesses to stay competitive and meet consumer demands for unique, high-quality products. With growing market demand and technological advancements, DTF printing is set to define the future of textile printing.