In the ever-evolving landscape of printing technology, the DTF gangsheet is revolutionizing how we create high-quality prints efficiently. Direct to Film (DTF) printing stands out with its ability to produce vibrant designs on various surfaces, and utilizing a gangsheet allows users to print multiple designs at once, maximizing efficiency. This introductory guide will walk you through everything you need to know to master DTF printing, from preparation to execution, ensuring your creations are nothing short of stunning. Whether you’re a seasoned professional or just starting out, our DTF printing tutorial will provide essential tips for gang sheet creation that will enhance your projects. Get ready to transform your printing process and achieve remarkable results with expert DTF printing techniques!

Direct to Film (DTF) printing introduces a groundbreaking approach to modern printing, especially when considering the advantages offered by gang sheets. By utilizing multi-design printing sheets, creators can reduce waste and streamline their printing operations, resulting in cost-effective production methods. This tutorial serves not only as a guide to DTF gangsheet optimization but also encompasses practical insights on preparing for print jobs effectively. With innovative techniques and updated DTF printing tips, you will learn how to manage designs efficiently on a single sheet. Dive into this dynamic world of DTF technology and elevate your creative possibilities!

Understanding the Basics of DTF Printing

DTF printing, or Direct to Film printing, is a revolutionary technique that has transformed the printing landscape. It enables vibrant, high-resolution designs to be printed onto a special film that can subsequently be transferred onto various products. The great advantage of DTF printing lies in its versatility; it can be used on a wide array of substrates, including fabrics, plastics, and even wood. This adaptability allows businesses and individual creators alike to produce unique items, ranging from custom t-shirts to promotional giveaways, effectively catering to diverse customer needs.

Moreover, the appeal of DTF printing is complemented by the quality of output. Drinkware, apparel, and other merchandise can feature intricate designs with an unparalleled depth of color. The process of creating a design using DTF technology generally involves preparing the digital artwork in compatible software, ensuring that the colors are vibrant and aligned with the printer settings. The use of gang sheets allows for multiple designs to be efficiently printed together, maximizing the printing space while minimizing production costs.

Getting Started with DTF Printing Tutorial

For those eager to dive into the realm of DTF printing, the first step is to familiarize yourself with the essential tools and techniques involved in the process. It begins with selecting the right software that suits your design capabilities. Programs like Adobe Illustrator and Photoshop are excellent for skilled graphic designers, while user-friendly alternatives, such as Affinity Designer, cater to beginners. Additionally, specialized DTF software can simplify the gang sheet creation process, making it accessible to anyone ready to start printing.

Once you’ve chosen your software, the next crucial step is to gather your materials. This includes high-quality DTF transfer films, compatible inks, and a capable DTF printer. Taking the time to prepare your workspace and ensure you have all materials ready can significantly streamline the workflow for your project. With a solid foundation in place, you can follow step-by-step guides that lead you through the design, print setup, and even post-processing aspects of DTF printing.

Tips for Efficient DTF Gangsheet Creation

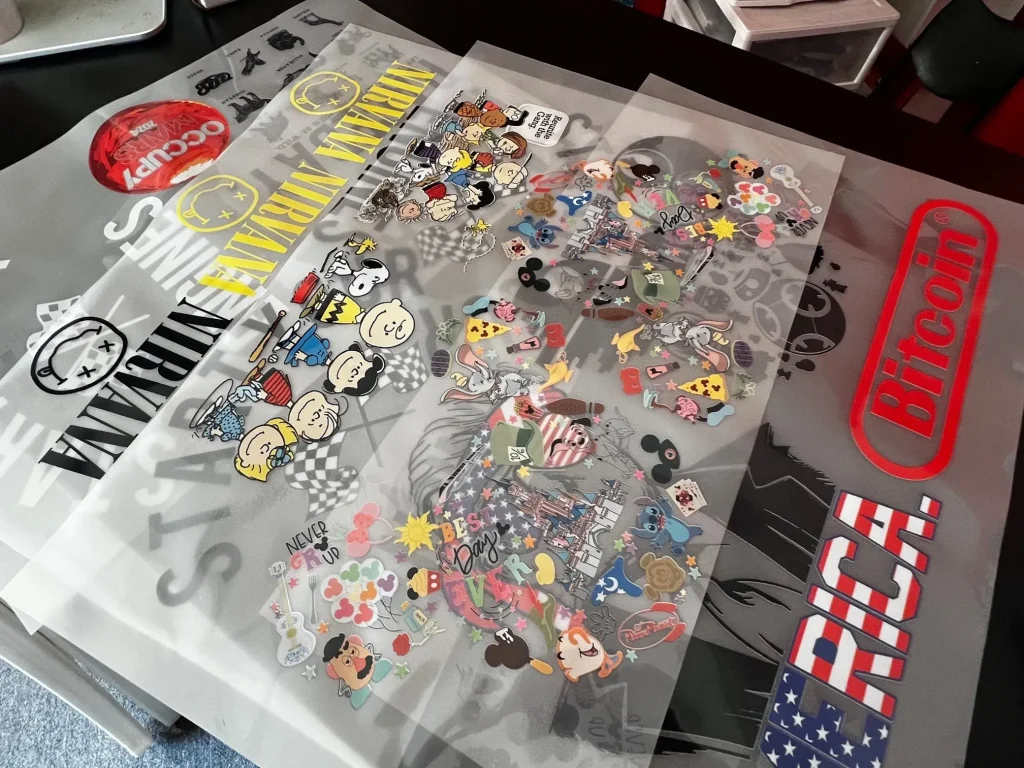

Creating an efficient DTF gangsheet can drastically improve your overall printing process. Start by organizing your designs thoughtfully—placing multiple images on a single sheet not only reduces material costs but also cuts down on printing time. Implementing grid layouts helps ensure each design is aligned properly, allowing for maximum utility of the print space. By minimizing gaps and strategically grouping colors, you enhance the efficiency of your workflow, leading to faster production times.

Additionally, keeping color management in mind is pivotal during gang sheet creation. Set your document to CMYK mode before printing to maintain color accuracy across all designs. Testing prints before finalizing your gang sheet can prevent costly errors and wasted materials. These simple yet effective tips will not only streamline your gang sheet creation but also ensure high-quality prints that meet your expectations.

Setting Up Your DTF Printer for Best Results

Once your designs are ready to go, the setup of your DTF printer becomes critical to achieving optimal results. Begin by carefully configuring your printer settings based on the type of DTF transfer film you will use, adjusting for factors such as media type and resolution. Many printers come with specific profiles designed for DTF printing, making it essential to explore these options for the best possible outcome.

It’s also important to ensure that your printer is equipped with the right inks. DTF printers typically require specialty inks that adhere well to the transfer film and substrate. Regular maintenance of your printer—like cleaning the printheads and checking the roller wheels—will contribute significantly to performance longevity, minimizing the chance of mishaps during critical printing sessions.

Post-Processing Techniques for DTF Prints

After successfully printing your designs on DTF transfer films, post-processing plays a vital role in ensuring the durability and quality of your prints. This step often involves curing the inks, which solidifies the design and allows for effective transfer onto your chosen substrate. Following the manufacturer’s guidelines for curing time and method is essential to prevent any issues with the transfer process.

Furthermore, consider additional post-processing techniques such as heat pressing, which enhances the bond between the film and the fabric. The heat press should be set to the appropriate temperature and pressure, ensuring a perfect seal that prevents peeling or fading over time. Being meticulous about these details makes a significant difference in the final product, helping to showcase the vibrant designs typical of DTF printing.

Engaging with the DTF Printing Community for Continued Learning

The DTF printing landscape is continuously evolving, making it crucial for enthusiasts and professionals alike to engage with the community. Online platforms such as Instagram, Facebook groups, and Reddit forums offer vast resources, insights, and shared experiences from fellow DTF printing practitioners. By participating in these environments, you can exchange ideas, troubleshoot issues, and discover new techniques that can enhance your printing skills.

Additionally, following relevant blogs and YouTube tutorials can offer ongoing education, introducing you to innovative practices and trends in DTF printing. This continuous learning will not only enrich your knowledge but also keep you at the forefront of industry developments, enabling you to adapt to new technologies and methods effectively.

Frequently Asked Questions

What is a DTF gangsheet and how does it improve DTF printing efficiency?

A DTF gangsheet is a layout that allows multiple designs to be printed on a single film sheet, maximizing space and reducing waste. This method enhances DTF printing efficiency by enabling users to print several designs at once, thus saving time and resources.

How can I create a perfect DTF gangsheet layout?

To create an optimal DTF gangsheet layout, use design software to efficiently arrange your graphics, minimize gaps, and group similar colors. This not only maximizes prints per sheet but also improves color management and print quality.

What software is best for DTF gangsheet creation?

Popular software options for DTF gangsheet creation include Adobe Illustrator, Photoshop, and specialized DTF software like Affinity Designer. Each offers unique features that cater to different expertise levels and design needs.

What are some essential DTF printing tips for using gang sheets?

Key DTF printing tips include ensuring high-resolution designs, managing colors in CMYK mode, performing test prints before finalizing, and regularly maintaining your printer for better performance and consistent results.

Why is color management important in DTF gangsheet printing?

Color management is vital in DTF gangsheet printing to achieve vibrant and accurate prints. Setting your document to CMYK mode and calibrating it against your printer’s output ensures that colors are represented correctly after the transfer process.

What materials do I need for a successful DTF gangsheet printing project?

For a successful DTF gangsheet printing project, gather DTF transfer film, compatible inks, a reliable DTF printer, and design software. Proper preparation of these materials can lead to a more streamlined printing experience.

| Key Point | Details |

|---|---|

| Introduction | Overview of DTF printing and its advantages. |

| What is DTF Printing? | High-quality designs on film transferred to various surfaces. |

| Preparing for Your DTF Printing Project | Steps include software choice, material gathering, and design prep. |

| Step-by-Step Tutorial | Instructions from opening software to post-processing. |

| Best Practices for DTF Printing | Optimize layout, maintain printer, and engage online communities. |

| Conclusion | Summary and encouragement to master DTF printing. |

Summary

DTF Gangsheet is an essential tool for anyone looking to create visually striking prints with maximum efficiency. This tutorial provides you with comprehensive step-by-step guidance, from understanding the basics of DTF printing to mastering the gangsheet creation process. With a focus on practical tips and community resources, you can significantly enhance your printing endeavors. Embrace the innovative DTF technology to not only elevate your crafts but also improve your business offerings. As you continue to learn and experiment, you’ll be able to produce stunning designs that truly stand out in any market.